Engineering Plastics: 3M Scotchply™ Material

___________________________

ScotchPLY is composed of a glass-based reinforcement infused with a thermoset epoxy resin matrix. What distinguishes this material from the usual G-10 / G-11 composites is its unique fabric layup. Instead of employing a crisscross pattern commonly found in NEMA grade composites (imagine a linen tablecloth), ScotchPLY adopts a unidirectional layup technique. This entails aligning all material strands in a single direction. The stacking of these unidirectional layers results in a product with remarkable flexural strength when compared to natural G10. For instance, in ASTM D229 testing, unidirectional ScotchPLY material achieves a strength of 166,795 psi, whereas natural Lamitex® G-10 only reaches up to 55,000 psi.

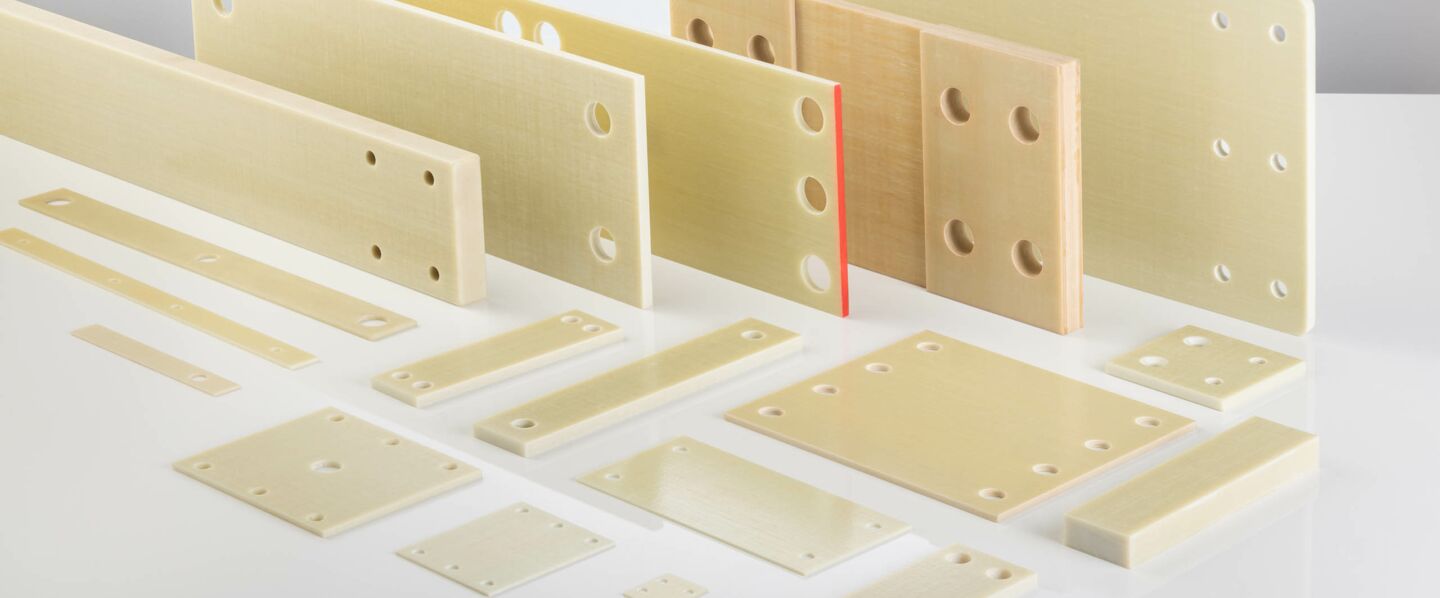

ScotchPLY™ Yellow (Standard)

The standard material from Tynic Automation for leaf springs made of fibre composite!

GFRP ScotchPLY™ Material

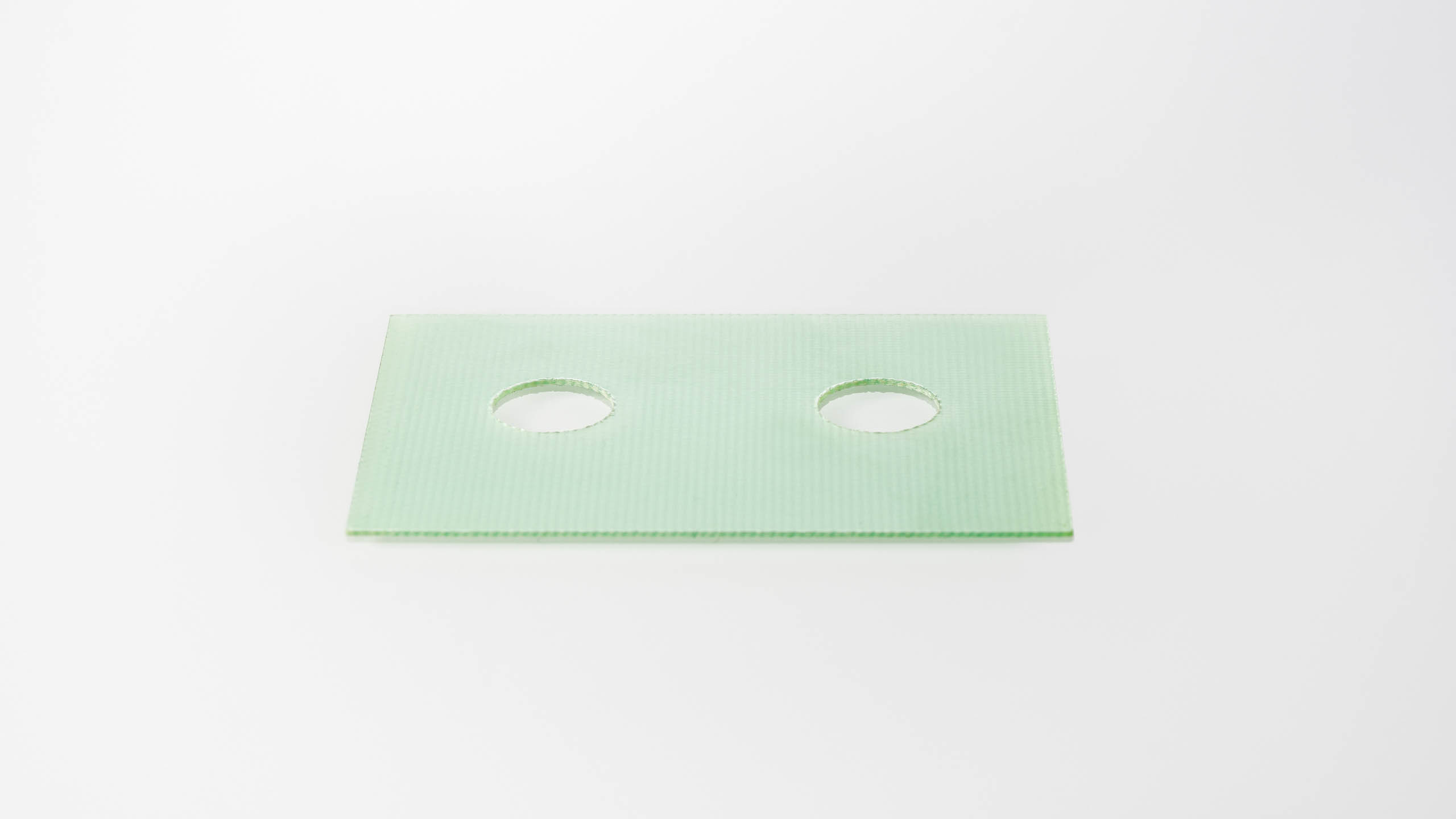

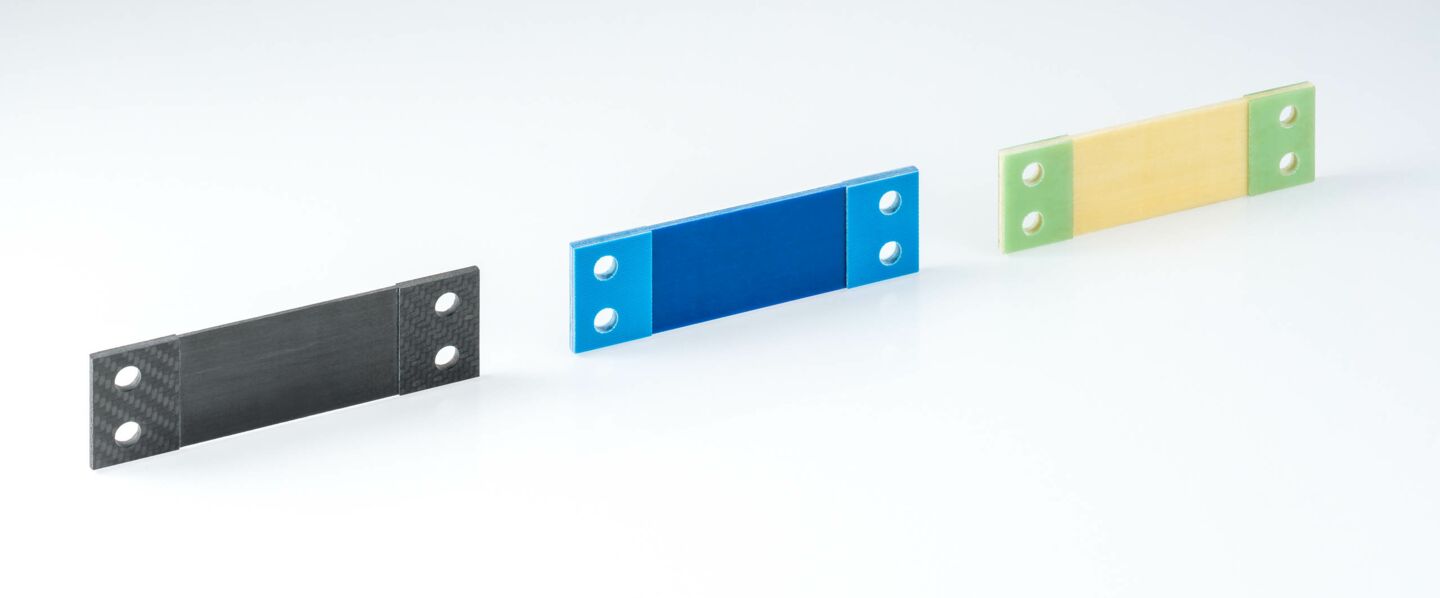

Glass fiber-reinforced polymer (GFRP), known for its strength and durability, serves as effective reinforcement, mitigating notching and shear stress during the installation of ScotchPLY® leaf springs. This material, comprising epoxy resin and glass roving fabric, boasts impressive electrical properties and maintains its mechanical robustness even at elevated temperatures. It is available both in loose form and directly bonded to leaf springs, seamlessly integrating into component finishes. Whether supplied pre-cut or customized according to specifications, including intricate curves or perforations, GFRP finds applications as spacer plates for composite leaf spring installations, press spacers, high-temperature-resistant machine parts, and high-voltage insulating components.

ScotchPLY™ Leaf Springs

ScotchPly® leaf springs consist of layered and compressed UD (unidirectional) prepreg plies. The mechanical properties of an ScotchPly® leaf spring may be adapted to customer requirements and application during production by orienting individual prepreg layers to each other. S-Ply® leaf springs offer superior properties to steel leaf springs in many applications.

The reinforcing fibres in the leaf springs consist of strictly parallel-oriented glass or carbon fibres that are not woven together. The fibres are not pre-stretched and not kinked. In contrast to metallic materials with an isotropic structure, they are direction-dependent and may therefore be aligned to form a material-specific design

ScotchPLY™ Leaf Springs – Applications

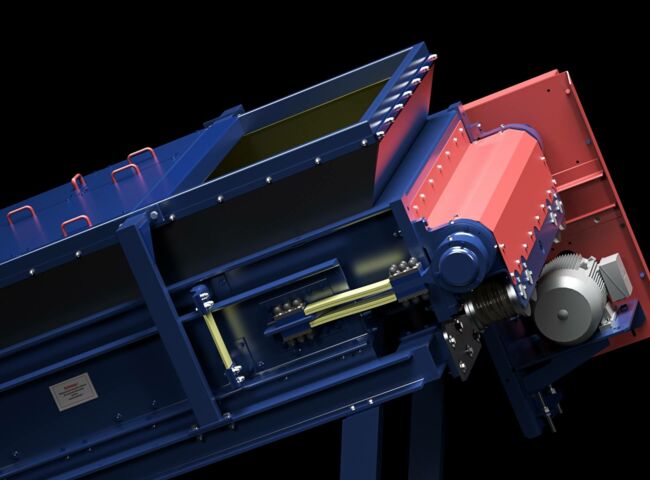

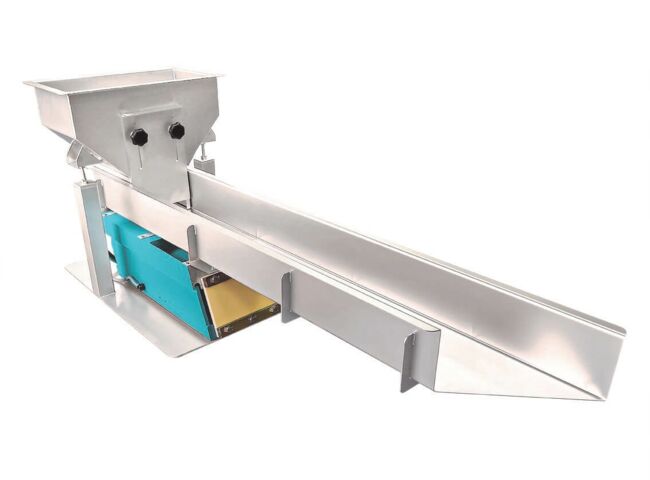

CONVEYING & SORTING

SCREENING TECHNOLOGY

DOSING SYSTEMS

Applications

Applications Include:

- Vibratory conveyors

- Furniture industry

- Automotive springs

- Vibratory feeders

- Electrical applications

- Trailer springs

- Vibratory screens

- Railroad joints

- Dock shelters

- Vibratory ball mill

- Composite coupling discs

Standard Sizing

Sheet 2M X 1M:

Please contact Tynic Automation for more information.

Stock Held In Brisbane, QLD.