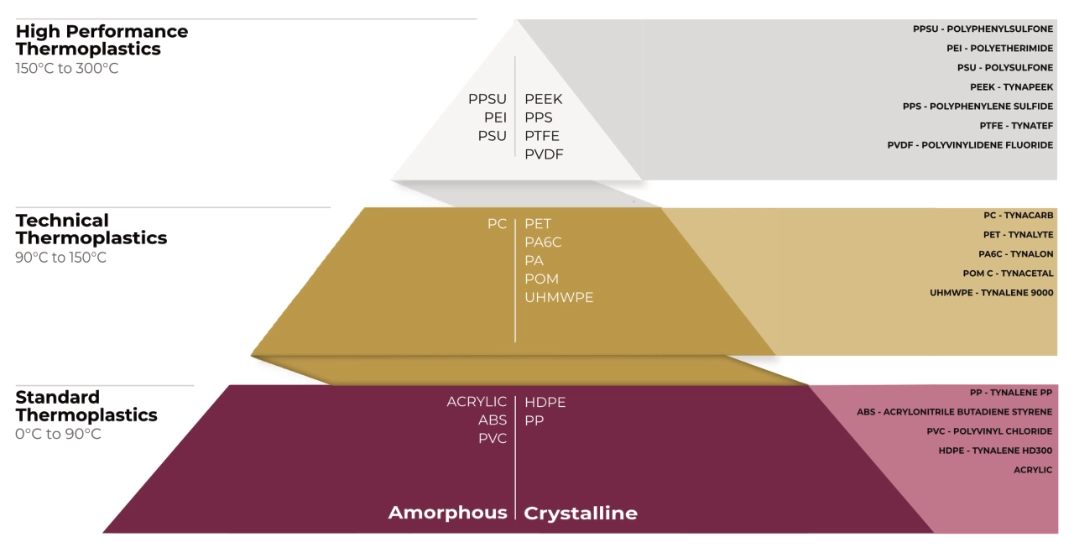

ENGINEERING PLASTICS RANGE

———————————-

Tynic is an engineering material & application pioneer in its field of plastics and their specific uses. With the support of state-of-the-art design & engineering techonology, Tynic offers the complete package from supply through to conception. With 11 CNC machining centers, Tynic is able to efficiently machine componentry with minimal tolerances and flawless finishes.

Engineering Plastics available in Cut To Size Plastic Material, Engineering Plastic Stock Shapes, Plastic Machined Components. View the Engineering Plastics materials guide to compare material mechanical properties.

HDPE

High Density Polyethylene (HDPE) is a highly versatile plastic material that finds use in a wide range of industries and applications. HDPE is a cost-effective option that offers excellent tensile strength, impact resistance, and resistance to chemicals in corrosive environments. It is especially suitable for applications involving contact with food, as it meets FDA/BfA requirements and has a low rate of liquid absorption. HDPE is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Cestilene™

- Tecafine™

- Polystone®

TYNALENE HD300

NATURAL

TYNALENE HD300

BLACK

TYNALENE HD100 (PIPE GRADE)

BLACK

POLYPROPYLENE – PP

Polypropylene (PP) is a mechanically stable polyolefin thermoplastic used within a wide variety of industries and applications. PP has excellent impact, chemical resistance, moisture absorption and machinability. In comparison to UHMWPE, PP has poor sliding characteristics and an average coefficient of friction. Typically utilised within the food, beverage & chemical manufacturing industries. Polypropylene is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Koterm™

- Hostalen™

- Polystone™

TYNALENE PP

NATURAL

UHMWPE

In the same polyethylene family as HDPE, Ultra-High Molecular Weight Polyethylene (UHMWPE) is dense, strong and abrasion-resistant. It’s especially well suited for holding up against wear from constant friction between moving parts. UHMWPE is fairly low cost and can be used for a wide variety of applications. Though it can be fabricated and machined, it’s not as well suited to forming specific shapes as HDPE. However, it is generally able to hold up better against friction and wear over time. Relevant for food related applications, UHMWPE is compliant with FDA/BfA requirements and is physiologically inert. UHMWPE is available in plastic sheet and rod, cut to size material and engineered plastic components.

Enhanced grades of UHMWPE include GLB and Lube X. Through the use of additives, GLB (Glass Bead Filled) and Lube X (Self-Lubricating) have increased abrasion resistance and sliding properties for harsh applications.

Similar to:

- Ertalene™

- Hostalen™

- Matrox™

- Okulen™

- Poly Hi Solidur™

- Polystone™

- Taffclad™

- Ultrapoly™

TYNALENE 9000

NATURAL

TYNALENE 9000

BLACK

TYNALENE 9000

BLUE

TYNALENE 9000 GLB

GREEN

TYNALENE 9000 LUBE-X

GREY

SafeGuard UV2™ – POLYCARBONATE

Polycarbonate (PC) is a transparent, amorphous thermoplastic with excellent impact strength and high dimensional stability. Its lightweight nature makes it ideal for outdoor applications, while its exceptional resistance to UV radiation makes it a premium grade material. Enhanced properties include excellent resistance to corrosive environments and electrical stability, as well as exceptional impact resistance. Polycarbonate is available in plastic sheet, cut to size material and engineered plastic components.

Similar to:

- Lexan®

- Makrolon®

- Sunloid®

- Sustonat®

- Tuffak®

SAFEGUARD UV2™

UV2

NYLON – PA

Nylon PA is produced through two methods: cast and extrusion. Cast Nylon demonstrates higher molecular weight and higher crystallization than extruded Nylon. Typically, Nylon is known for its high mechanical strength, good wear resistance, sliding function, and great machinability. In contrast to polyethylene products, Nylon absorbs moisture and is prone to expansion; as a result, it is not recommended for wet environments. Each grade of Nylon is manufactured to have different characteristics, such as self-lubrication, wax-filled, UV resistance, and more. Nylon is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Sustamid™

- Tecamid™

- Ultramid™

- Ertalon™

- Nylatron™

- Ensilon™

- Zellamid™

TYNALON

T-GLIDE

TYNALON

NGO YELLOW

TYNALON

IMPACT

TYNALON

NATURAL

TYNALON

MOLY

TYNALON

HR BLUE

TYNALON

NGO GREEN

ACETAL – POM

Acetal (POM-C) is a semi-crystalline thermoplastic with good dimensional stability and frictional properties. It contains high mechanical strength, toughness and provides an ease of machining not present in other plastics. Acetal is primarily for customers in which precision componentry with small tolerances are of importance. In contrast to Nylon, Acetal provides very low moisture absorption, making it a necessity for applications within a submerged or wet environment. This is due to its ability for mechanical properties to be maintained through wet or harsh environments. Chemically resistant, Acetal is also a great choice for corrosive conditions. Acetal is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Delrin™

- Ensital™

- Ertacetal™

- Sustarin™

- Tecaform™

- Zellamid™

TYNACETAL-C

NATURAL

TYNACETAL-C

BLACK

TYNACETAL-C

FOOD GRADE BLUE

POLYESTER – PET

PET (Polyethylene Terephthalate) is a plastic material with high crystallinity, offering excellent mechanical strength and dimensional stability. It also has good sliding properties, wear resistance, and electrical properties. PET is known for its ability to maintain its mechanical and electrical characteristics even when exposed to moisture, making it a popular choice for applications where moisture resistance is important. Due to its properties, PET is often used as a lightweight and cost-effective replacement for traditional metals. PET is available in plastic sheet and rod, cut to size material and engineered plastic components.

To enhance the mechanical properties of PET, a solid PTFE lubricant is added to the basic polyethylene terephthalate polymer, creating TYNALYTE-ZX.

Similar to:

- Arnite®

- Ensitep®

- Ertalyte®

- Rynite®

- Sustodur®

- Tecadur®

- Zellamid®

TYNALYTE

NATURAL

TYNALYTE

ZX GREY

TYNALYTE

SW BLACK

TEFLON – PTFE

PTFE (Polytetrafluoroethylene) or Teflon is a highly fluorinated plastic material with exceptional chemical resistance and a low coefficient of friction. Its unique chemical structure, consisting of a carbon-fluorine bond, provides excellent abrasion resistance and sliding properties, making it ideal for applications involving constant friction. PTFE also maintains its mechanical properties in harsh environments, including extreme temperatures up to 260°C and exposure to UV radiation. PTFE is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Ensital™

- Rulon™

- Tetron™

- Unasco™

- Zellamid™

TYNATEF

PTFE NATURAL

PEEK

PEEK (polyetheretherketone) is a premium, high-performance semi-crystalline engineering plastic that offers exceptional properties. With excellent chemical resistance and low moisture intake, it is incredibly tough and strong, making it ideal for applications where thermal, chemical, and combustion properties are critical to performance. PEEK’s mechanical strength remains stable across a broad temperature range, and it maintains its stiffness and strength in harsh high-pressure and high-temperature environments. PEEK is a versatile material that offers a reliable and long-lasting solution for demanding applications. PEEK is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Ketron™

- SustaPEEK™

- Sustatec™

- TecaPEEK™

- Victrex™

- Zellamid™

TYNAPEEK

BEIGE

TYNAPEEK GF30

BEIGE

G-ETRONAX – EPOXY GLASS FABRIC

G-Etronax are carefully composed resins combined with a glass base. This results in not only in exceptional resistance, but also amazing electrotechnical properties, making G-Etronax suitable for countless applications.

G-Etronax is incredibly strong and retains its high mechanical strength even at high temperatures. This material thus has a high thermal stability, and some types of G-Etronax can be used at up to 210°C. Certain selected qualities are also fire-retardant, which is why just the thermal properties alone make G-Etronax a highly versatile material. EP11 Epoxy Glass Fabric is available in plastic sheet, cut to size material and engineered plastic components.

Similar to:

- Bakelite™

- Durostone™

- Lignostone™

- Scotchply™

G-ETRONAX

EP11 EPOXY GLASS FABRIC

POLYVINYL CHLORIDE – PVC

Polyvinyl Chloride is an amorphous engineering plastic with high mechanical stability. PVCU characteristics include rigidity, excellent chemical resistance and high strength. With a softening temperature of 90°C. Recommended operating temperature range is between -15°C and 60°C. Perfect for use in an extensive range of chemical, construction and electrical applications. PVCU is not appropriate for use in severe UV or food safe environments. PVC is available in plastic sheet and rod, cut to size material and engineered plastic components.

Similar to:

- Weartherm™

- Takiron™

- Polor™

- Suloid™

- Simona PVC™

TYNAVIN

PVCU

SCOTCHPLY™ Composites

ScotchPLY™ is composed of a glass-based reinforcement infused with a thermoset epoxy resin matrix. What distinguishes this material from the usual G-10 / G-11 composites is its unique fabric layup. Instead of employing a crisscross pattern commonly found in NEMA grade composites (imagine a linen tablecloth), ScotchPLY adopts a unidirectional layup technique. This entails aligning all material strands in a single direction. The stacking of these unidirectional layers results in a product with remarkable flexural strength when compared to natural G10. For instance, in ASTM D229 testing, unidirectional ScotchPLY material achieves a strength of 166,795 psi, whereas natural Lamitex® G-10 only reaches up to 55,000 psi.

Similar to:

- Bakelite™

- Durostone™

- Lignostone™

- Scotchply™

ScotchPLY™

Yellow

ScotchPLY™

GFRP Green