Fiberflon PTFE Coated Belts – Seam and Edge Grades

PTFE Seam Methods

Alligator Splice: These splices are the most durable and easiest to use. Belts utilising alligator or clipper splices can be installed without taking machinery apart. A cover flap can be added to reduce heat transfer to your material.

Clipper Splice: Similar in application to the Alligator Splice, the clipper splice contains a double-staggered grip pattern, offering quick, economical installation.

Peek Splice: Peek splices are an ideal choice when metallic splices cannot be used. Either a peek or smart loop splice should be chosen when maximum airflow is desired.

Self Loop Splice: Self loop splices utilise a 1.5″ fold over onto itself and can be heat sealed or sewn. Self loop splices offer maximum airflow and are recommended for narrow belts.

Fabric Notched Splice: A fabric notched splice is similar to the alligator splice but completely eliminates the metal clip. It uses a PTFE Kevlar® material with a special pin joint.

Butted Splice: The ends of the belt are butted together and joined by sealing a strip of reinforcing fabric under the butted ends. Butted splices provide the smoothest belt surface at the joint and eliminate the step-down surface which is characteristic of the overlap splice.

Overlap Splice: This is the standard splice for most applications. Overlap splices, normally cut and overlapped on a 90, 60 or 45 degree angle, are also commonly used since they are more flexible when running on smaller diameter rollers. Standard overlap splices are 1″.

Scarfed Splice: To prepare a scarfed splice, the ends of the belt are “scarfed”, or sanded down and joined, eliminating the double thickness at the splice which is characteristic of the overlap splice. A scarfed splice also eliminates the need for a heat-sealed reinforcement at the splice, a characteristic of the butt splice.

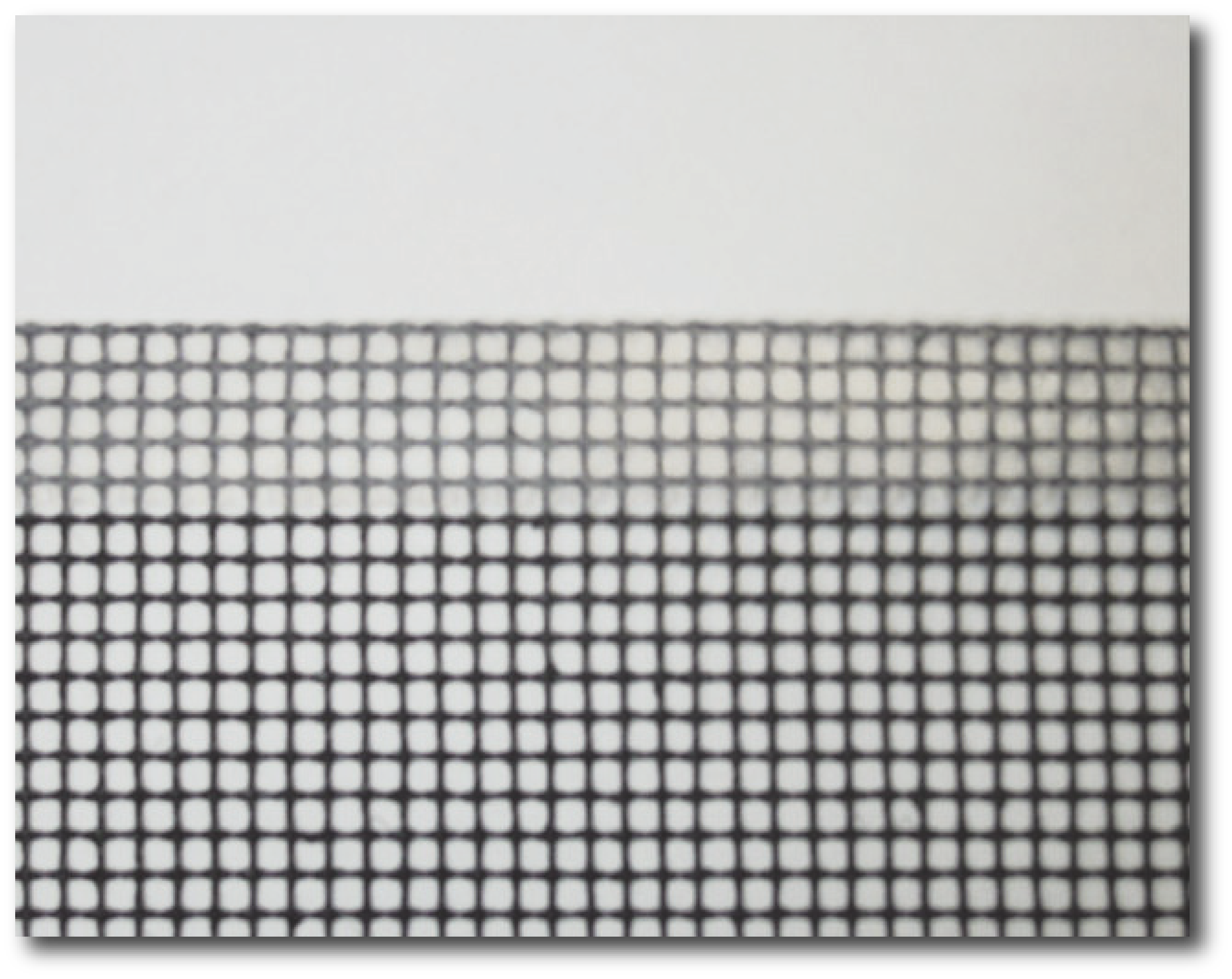

PTFE Edge Grades

Fiberflon belts can be supplied with strips of heat-sealed film or fabric on one or both edges of the belt. This reinforcement serves a dual purpose: it reduces fraying of belt edges which rub on guide rollers and it also provides the strongest possible anchor for guiding pins, snaps and grommets. PTFE edge grades include:

Heat-Sealed PTFE Film Edge: PTFE film edges are heat-sealed to the top and bottom of the edges of the belt. The film is available in 3 mm black or clear and 10 mm tan ( for 1″ surface only).

Heat-Sealed Fabric Edge: Six mm fabric is heat-sealed to the top and bottom of the edges of the belt for a 1″ (standard) or 2″ surface. Fabric edges are available either tan or black.

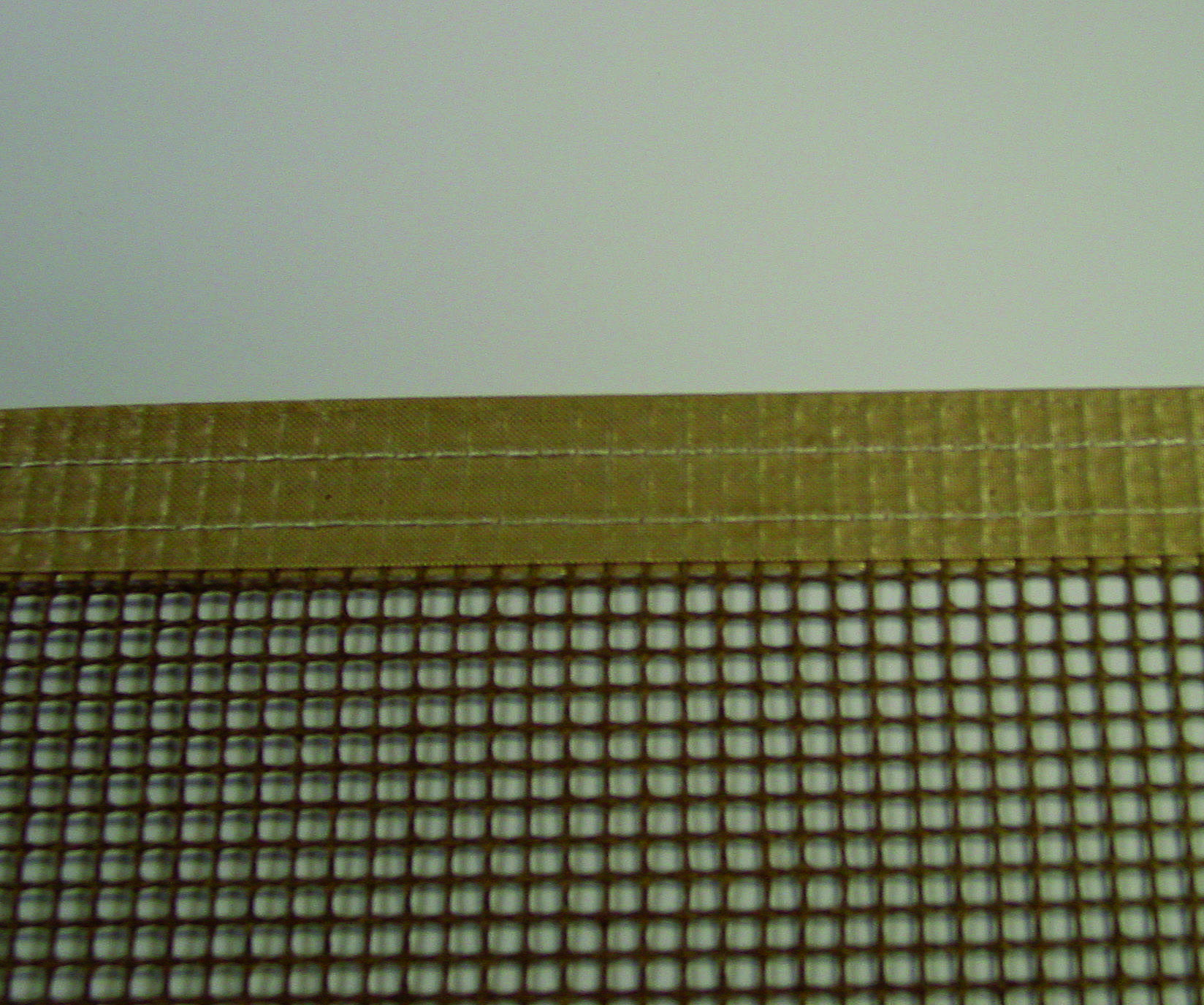

Sewn Fabric Edge: For extra reinforcement, our 6 mm heat-sealed fabric edge can also be sewn if desired. This reinforcement is commonly used on open mesh belting.