Fiberflon PTFE Coated Belts – Tracking & Guiding Systems

A guiding system is essential for most of PTFE coated belting. Guiding may be by external guiding systems or by combining a system in the belt construction, such as metal studs, PTFE pins or eyelets. External, electrical or mechanical systems are preferred, due to suitability for all widths of belts and the prolonging of belt life by preventing edge tracking damage.

Tips for optimizing belt life – Run at low tensions, use only flat rollers, ensure each roller is aligned properly and utilize an automatic guiding systems.

Snaps: The belts run with tracking studs inserted into the edge of the belt that locate into a machined groove within the rollers of the conveyor. This prevents the belts from tracking off and extends the belts life.

Grommets: Nickel Grommets provide reinforced holes which are designed for tracking systems that use chains and springs.

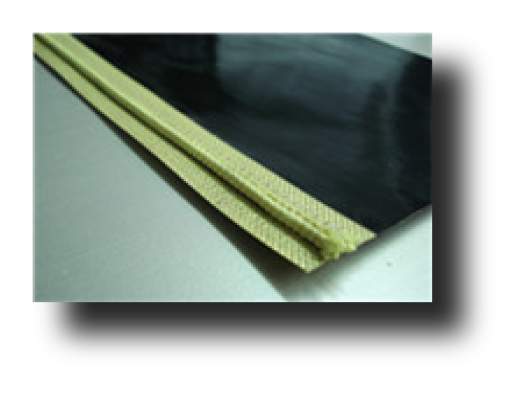

Kevlar Guides: The belts run with tracking Kevlar guides inserted in to one edge of the belt that then locate in to a machined groove in the rollers of the conveyor. This prevents the belts from tracking off and extends the belts life.

Silicone Rubber Guide: The belts run with tracking silicone guides inserted in to one edge of the belt that then locate in to a machined groove in the rollers of the conveyor. This prevents the belts from tracking off and extends the belts life.

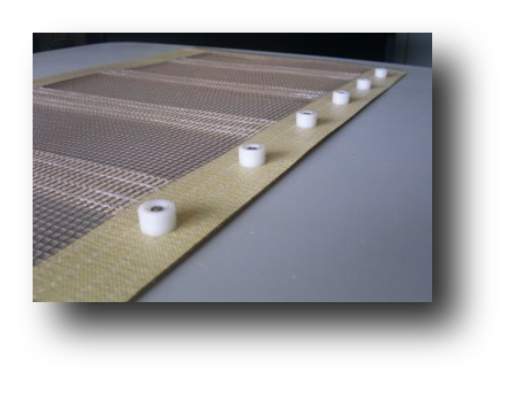

PTFE Pin Guides: 16 mm Ø x 12 mm H Teflon Pin Guides are available on one side of any type belt. Kevlar edge reinforcement is recommended for strong connection pin guide to the belt. This type of pin guide is resistant up to 260°C temperature.

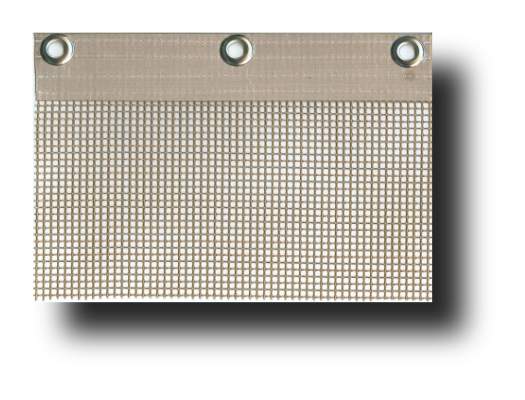

Metal Eyelets: A wide range of diameter eyelets are available for any belt type. The eyelets are connected to springs for consistent belt tracking.

Two-Ply Belts: Two-ply belts are constructed of two plies of PTFE coated fibreglass laminated together with staggered splices. This provides a smooth, continuous thickness along the entire belt length which guarantees a uniform seal in packaging and heat-sealing applications. The belts are typically available in widths of 1/3″ to 3″.