Partnered with REGINA, Tynic Automation supplies conveyor chain and accessories for the bottling, food, glass manufacturing, and packaging industries. With a focus on durability and innovation, Tynic ensures that our product range meets the demanding requirements of these industries, even in challenging environments.

REGINA Gripper Chains

Regina gripper chains are designed for handling containers at different heights on elevators, lowerators, and to pass through rinsers. Equipped with pre-lubricated steel base roller chains, REGINA guarantees long-lasting chain efficiency.

Steel Chain Grades: Carbon Steel, Stainless Steel, and Enduro Steel.

Flight Grades: Low Friction Acetal and DK2 (Kevlar Reinforced).

Rubber Pad Material: Thermoplastic Rubber and Heat Stabilized Rubber.

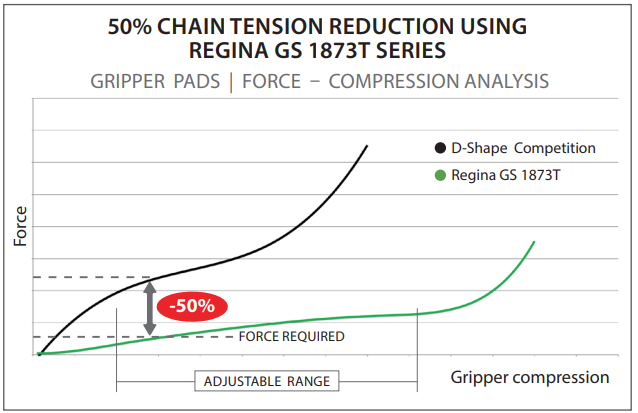

The D-Shape Regina gripper chain (GS 1873T) offers a flat and more continuous contact surface between the rubber part and the conveyed product. The force applied to the conveyed products remains controlled and uniform.

The Short Finger Regina gripper chain (GW 1873T) is designed to exert a higher force on the conveyed products. Particularly suitable for conveying heavier containers and packaged products.

The Long Finger Regina gripper chain (EW 1873T) demonstrates increased flex without increasing the force over product and conveyor. This is particularly suitable for conveying empty glass and Pet containers.

D-Shape Gripper Chain Advantages

Some side-grip conveyors with long rubber fingers often cause a kick-out effect, leading to falls and downtime. The new GS 1873T gripper chain, with its special rubber pads, solves this issue, providing maximum stability for all container types. Other benefits include easier cleaning, improved chain quality, and reduced load on bottles, motors, and drives.

Recent Comments