Stainless steel mesh belts play a critical role in a wide range of industrial processes, from food production to high-temperature conveying. Their durability and open structure make them essential in demanding environments. This overview explores common applications and provides guidance on identifying the right belt type for your requirements

SS Mesh Belt Applications

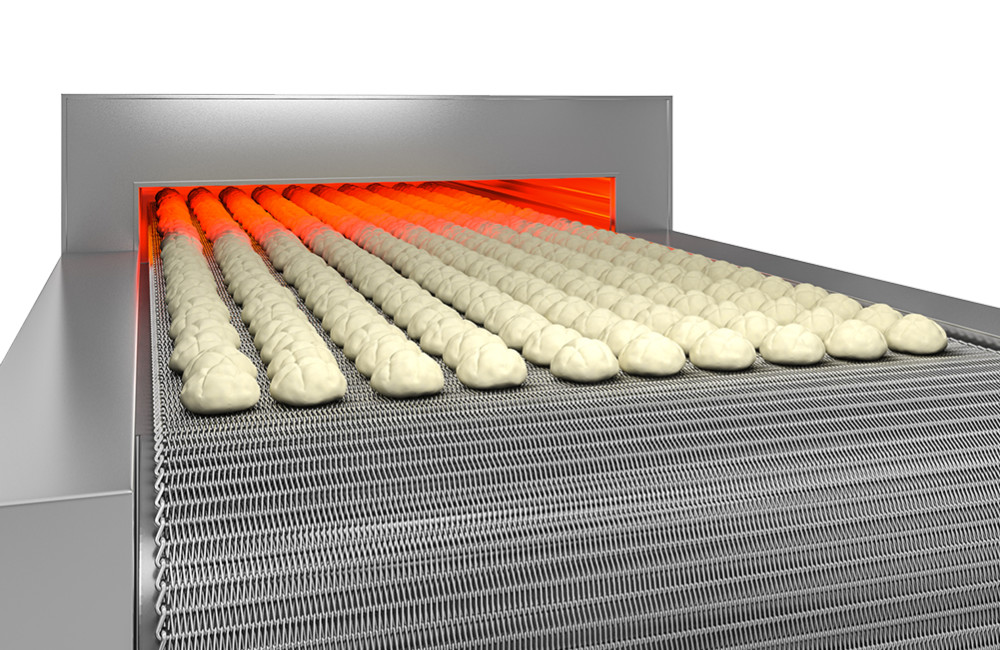

Cooking & Freezing

In high or low-temperature zones, mesh belts enable even heating or rapid cooling. Their strength and airflow support make them ideal for ovens, chillers, and freezers handling delicate or irregular products.

Washing, Drying & Coating

Stainless steel mesh belts support efficient rinsing, drying, and coating by allowing excellent drainage and airflow. Ideal for baking, produce, and snack lines, they provide a clean, stable surface through wet or finishing stages.

Heat Treatment

Mesh belts are ideal for processes requiring consistent, controlled heat. Their open design allows even thermal transfer, making them suitable for annealing, setting, curing, or texturing products at high temperatures.

Choosing the Correct SS Mesh Belt

Selecting the right stainless steel mesh belt is vital for reliable performance and longevity. Different belt designs vary in wire thickness, weave, and open area, affecting product support, airflow, and durability. Contact Tynic for more information.

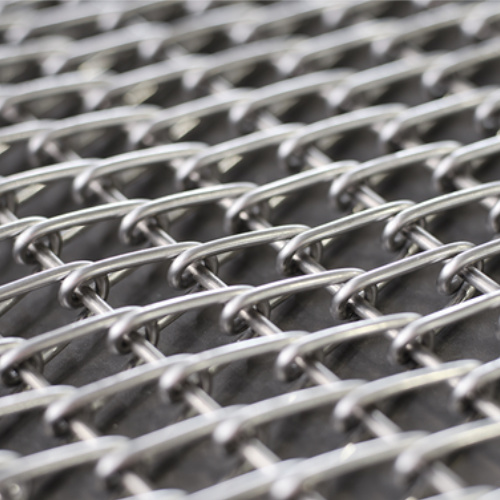

Balanced Spiral Belt

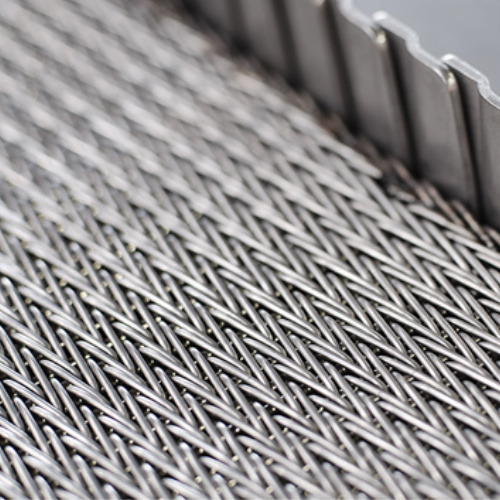

Compound Weave Belt

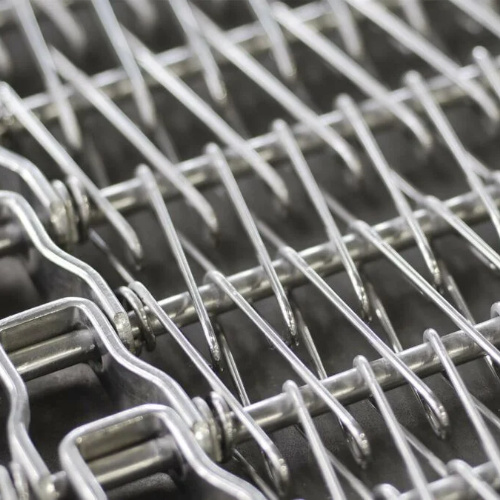

Rod Network Belts

Balanced Spiral Belt

Compound Weave Belt

Rod Network Belts

Replacing Your Current SS Mesh Belt?

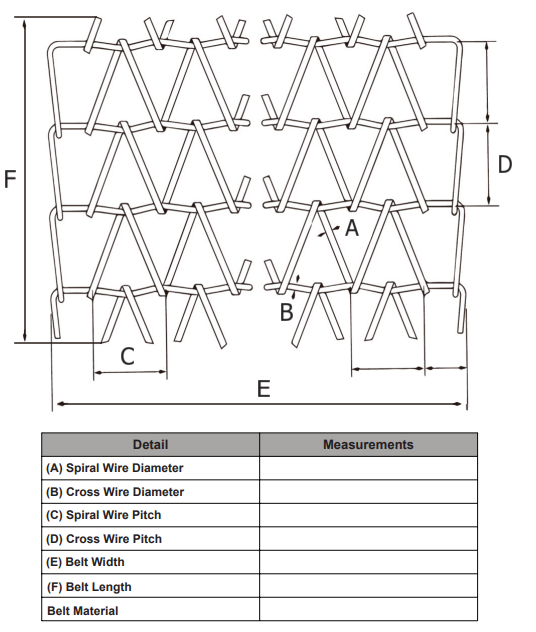

Tynic simplifies the process of identifying and replacing stainless steel mesh belts by providing clear, structured identification forms that capture all critical dimensions and specifications. These forms help ensure accurate reverse engineering, even when original drawings or part numbers are unavailable.

Recent Comments