Shatter material performance expectations with carbon graphite components, the benchmark for glass manufacturing and high-temperature applications. Partnered with global leaders in graphite manufacturing, Cova GmbH, Tynic supplies engineered carbon graphite materials and componentry.

Why Graphite?

Graphite’s extensive mechanical properties create the ideal candidate for applications within harsh, high-temperature environments. Properties include:

- High Oxidation Resistance – Graphite can withstand extended exposure to elevated temperatures.

- Self-Lubricating – No need for oil or grease lubricants.

- High Thermal Conductivity – Heat travels extremely quickly through graphite, therefore, molten glass will not be exposed to sudden uneven temperature distributions.

- Soft Material – Graphite is very unlikely to scratch/damage glass or precious materials.

High-Temperature Applications:

Carbon graphite is not a common material choice for the average consumer. While many of us may not be aware of it, carbon graphite parts are used in a variety of applications. Popular industries for carbon graphite applications include:

- Mining and Transportation

- Automation

- Space and Defence

- Manufacturing

- Energy Production/Storage

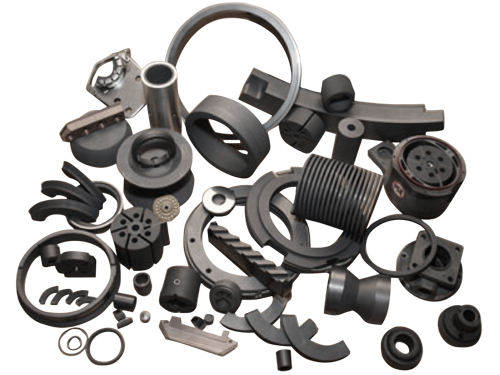

Common Componentry:

- Insulation Componentry and Refractory Systems

- Reaction Vessel Linings

- Bearings, Heat Exchangers and Steam Nozzles

- Piston, Guide and Packing Rings

- Mechanical, Segmented and Contactless Seals

Recent Comments