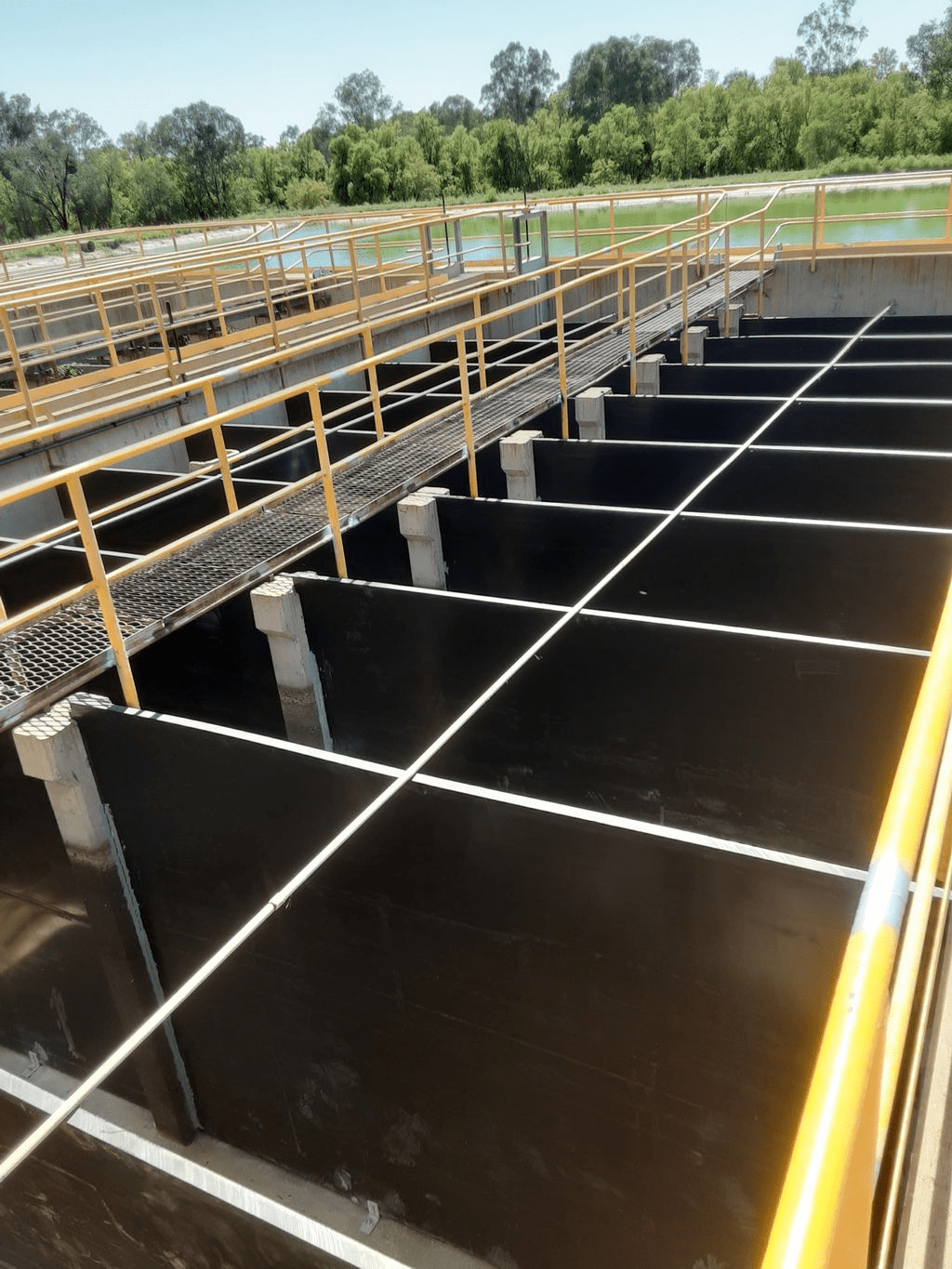

Tynic’s High Preformance HDPE Material Provides a Reliable Solution For Blackwater Waste Filtration & Processing Plant.

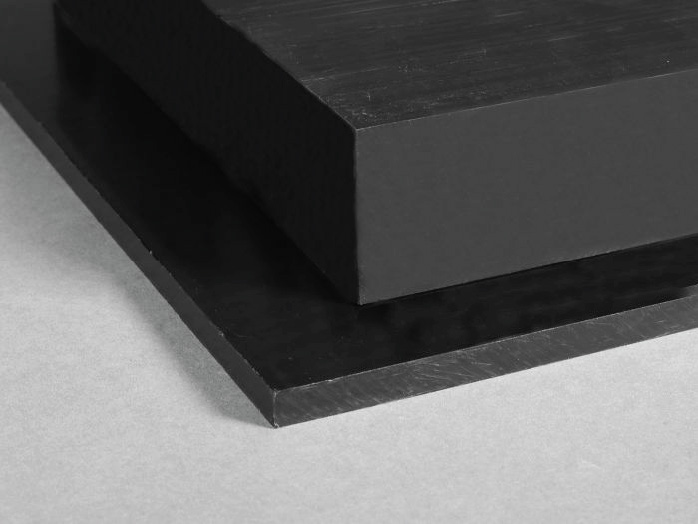

One of Australia’s largest site maintenance and management companies required 36 sheets (15 tonnes) of TYNALENE HD300 black, UV safe plastic. The material was required to construct baffles within the Blackwater waste filtration plant.

A baffle is an object or material utilized to restrain and restrict the flow of a fluid, gas, element or sound/light from reaching a particular direction.

After consulting with the customer on design specifications, it was established that the baffles were required to measure 3.7mx2.6mx40mm.

The client prioritised that the product must achieve a scheduled estimated material life, strong UV resistance and maintain mechanical stability during operation. Tynic was able to exceed the material performance expectations.

Another encountered problem was the dispatch of large sheeting to a rural location. Tynic opted to weld half length material sizes to reduce the difficulty of dispatch to Blackwater.

Despite encountering dispatch and logistical issues, Tynic was able to provide the order on time and satisfy the customers requirements, ensuring the construction of the filtration plant was kept on schedule.

Industry: Water Treatment & Processing

Application: Blackwater Treatment Plant

Problem / Requirement: 15 tonnes (36 sheets) of 3.7mx2.6mx40mm black UV resistant HDPE with a challenging list of requirements.

Solution: High performance TYNALENE HD300 Black baffles.

Result: Tynic successfully catered to the needs of the treatment plant, providing technical knowledge and expertise for plastics within a water treatment application.

Recent Comments