Often considered the highest class of engineering plastics, PEEK has a 260°C max continuous operating temperature and highly stable chemical structure. On a long term basis, cost of componentry can be significantly reduced with PEEK, responsible for prolonging component lifetime, cutting downtime costs and maximising production efficiency/quality.

Why Choose Peek?

PEEK can be used as an alternative to other materials, including glass, steel, aluminium, and other polymers. The key benefits to Peek include having extremely high strength to weight, excellent heat tolerance, it’s long lasting as well as hydrolysis and chemical resistance. The material’s strength is complemented by its high purity and lubricity for challenging friction applications.

PEEK Industry Applications

Food/Beverage Manufacturing:

Production within the food and beverage industries often require increased temperatures, static and chemical resistance. These properties are necessary within processes such as food drying, which requires temperatures as high as 150°C. PEEK exceeds quality and safety regulations, complying with FDA and BfR requirements.

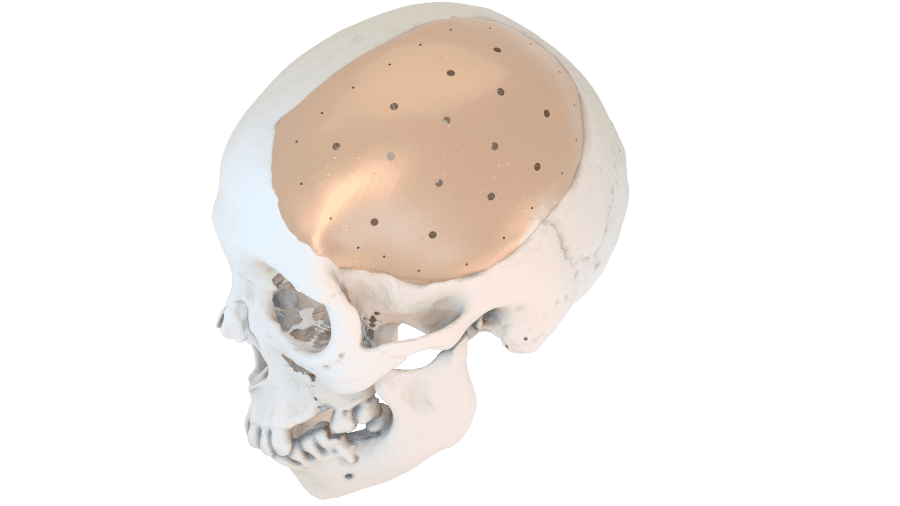

Medical/Pharmaceutical:

PEEK is used within the medical industry as an implant material. As opposed to traditional metals, PEEK is flexible, durable and does not harm the body or skin. This is particularly applicable within cranial implants, as superior, tough and lightweight implants are essential for day to day operation.

Another application in which PEEK is a reasonable replacement for traditional materials is a dialysis pump filter. The pumping mechanism often causes severe problems, thus, a good pump material that isn’t affected by temperature fluctuations and moisture is required.

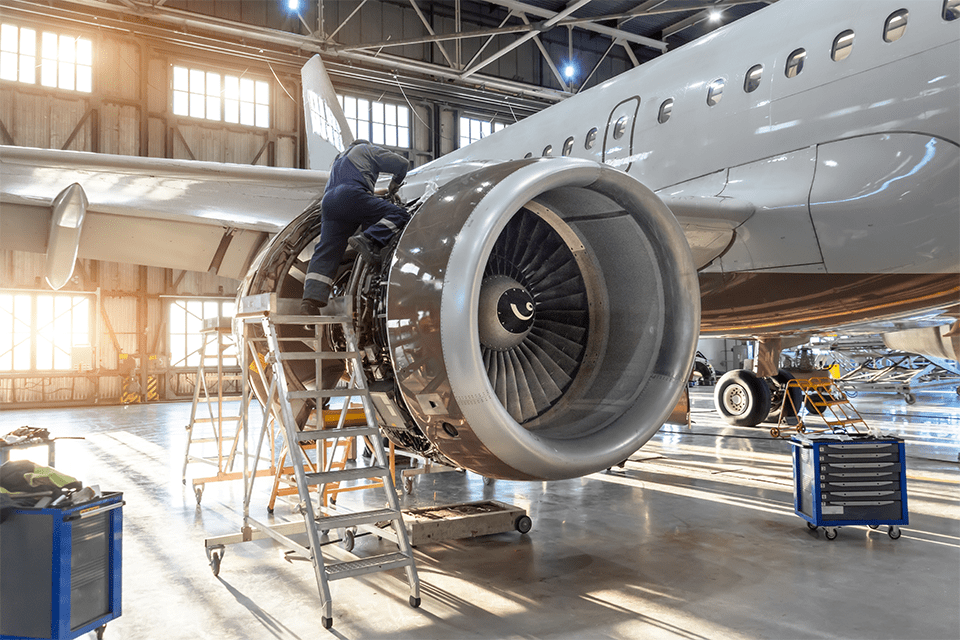

Aerospace & Automotive:

Aircraft manufacturers prefer PEEK as it is 70% lighter than steel. This makes it easier to save on fuel, significantly improving fuel efficiency. Components made of PEEK are chemically resistant to fuel, de-icing solutions, steam, salt, water, and hydraulic fluid.

The automotive industry makes use of PEEK due to its chemical and heat resistance. PEEK is a true workhorse, capable of handling punishing environments with ease. Typically used within the automobile industry due to excellent performance within braking systems, clutches, sensors, climate management, running gears and engine management systems.

Recent Comments