Established in 1971, Intralox is a global powerhouse in conveyance solutions, assisting with the production and movement of critical products. Often credited with the invention and first patent of plastic & rubber modular belting, Intralox is constantly innovating and improving the standard of conveying solutions.

Product Range

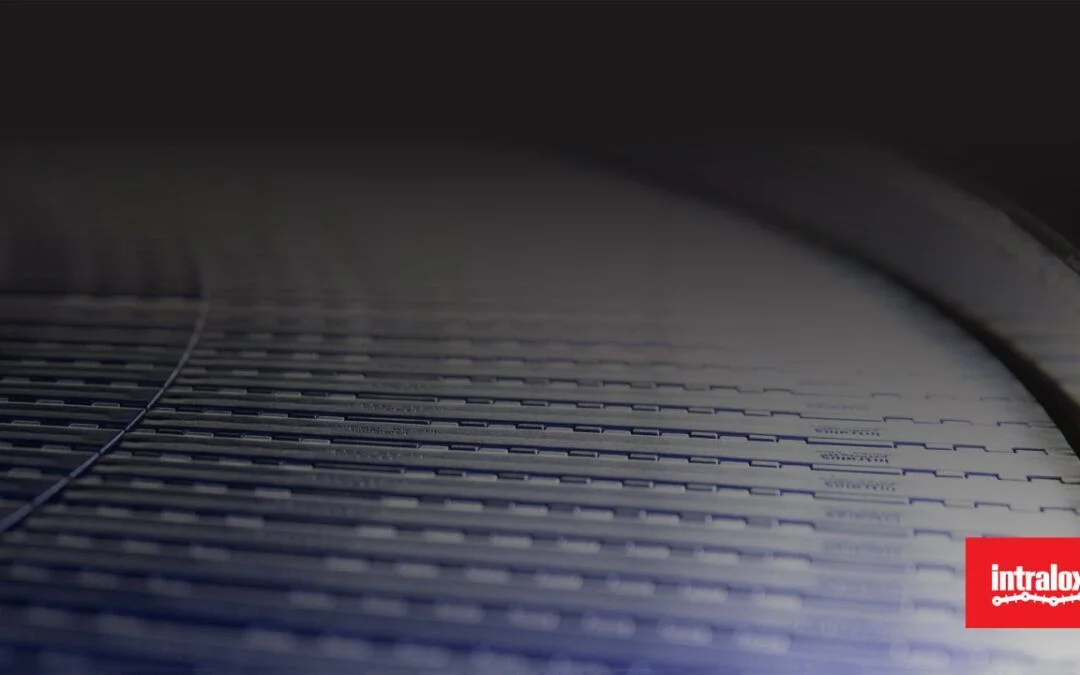

Modular Plastic Belting: Intralox’s modular belt range has been setting industry standards for more than 50 years. Available in hundreds of thousands of configurations, Intralox modular belts can be found anywhere products are processed, manufactured, or moved.

Modular construction, combined with lighter weight materials and expert engineering, ensures Intralox belts:

- Are easier to install, repair, clean, and maintain.

- Increase your throughput while minimizing downtime.

- Provide longer belt life—up to three times as long in some applications.

ThermoDrive Belting: ThermoDrive® technology offers the same reliability as our modular plastic belting, with the added hygiene benefits of a solid thermoplastic structure. Lightweight and easy to install, the ThermoDrive belting system eliminates the tensioning, tracking, and cleanability issues that often arise with traditional flat or tensioned positive drive belts.

ThermoDrive technology’s patented tensionless system combines belts and components to help food processors:

- Overcome complicated, time-consuming cleaning and sanitation processes

- Eliminate belt issues caused by tensioning (e.g., mistracking, elongation, wavy edges)

- Avoid hygienic risks posed by fabric belts or exposed fabric or yarn reinforcements

Active Integrated Motion™ Equipment: Intralox Active Integrated Motion™ equipment is used in gentle product handling applications across several industries, including food processing and packaging. AIM sorting, switching, and merging equipment is designed to perform in multiple environments, including washdown, to promote cleanability and line flexibility and reduce dependence on labour. With AIM technology, you can increase throughput, protect product integrity through gentler handling, and decrease safety concerns and risks.

Activated Roller Belt™ Equipment: Intralox’s patented Activated Roller Belt™ technology enables increased flexibility, high throughput, reduced footprint, gentle product handling, and simplified controls. Our approach to layout optimization is key to ARB technology’s success, enabling efficient and reliable sorting, merging, turning, and singulating across a wide range of industries.

Spirals: Spiral conveyors are critical pieces of equipment for many industries, especially food processing and container manufacturing. The right spiral solution can bring efficiency to conditioning processes like freezing, cooling, or proofing; the wrong solution can bring your entire line to a halt.

Intralox’s modular plastic spiral conveyor belts and solutions help you:

- Minimize expensive, unscheduled production downtime.

- Eliminate complicated repair work.

- Overcome product quality and orientation challenges.

Recent Comments