Tynic’s Reverse Engineering Provides Cost Effective Solutions For Industry

Equipped with a state of the art engineering department, Tynic Automation is able to reverse engineer and redesign components at lower costs then OEM manufacturers. Tynic also optimises component efficiency with a specialised range of Engineering Plastics.

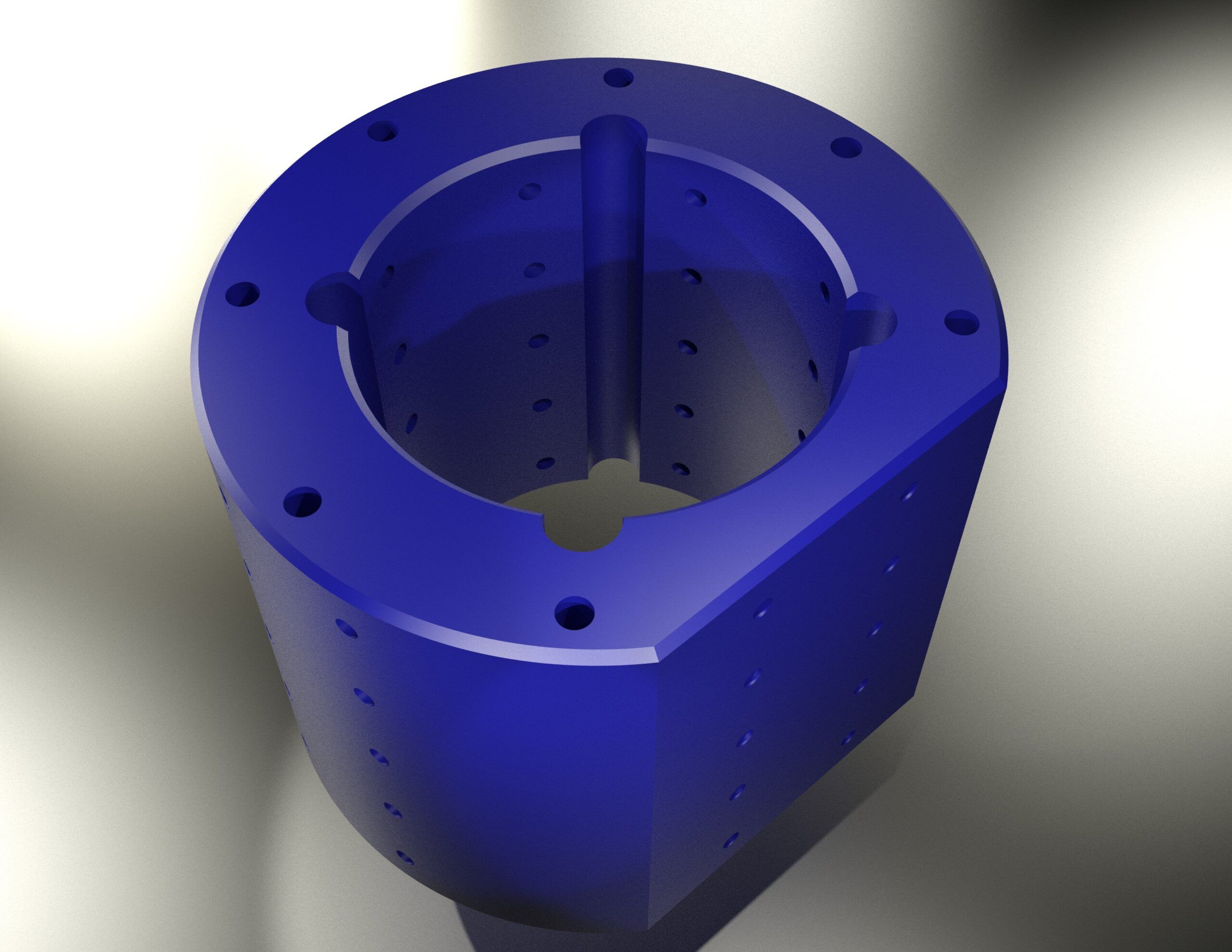

An example of Tynic’s reverse engineering capabilities was recently demonstrated during the development of our aftermarket USF Contra Shear Bushes. After paying a substantial premium for USF Contra Shear Bushes for years, the largest water treatment plant in the Southern Hemisphere finally decided to approach Tynic for assistance. A USF Contra Shear Bush is used as a filter on top of a waste filtration conveyor screw, removing water from the waste being pushed up the screw.

USF Contra Shear Bush

Wastewater Treatment Plant

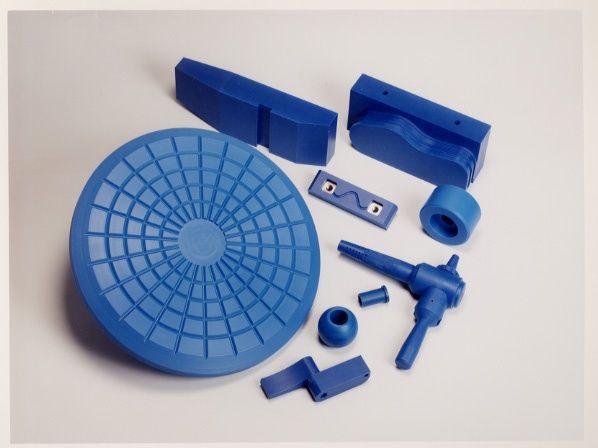

The Contra Shear Bush is manufactured with Tynalon HR Blue. Additives in the form of high temperature resistant colorants, heat stabilisers and a low coefficient of friction allow this material to retain mechanical properties in applications within extreme operating conditions. As a result, Tynic was able to exceed cost, performance and service expectations.

Recent Comments