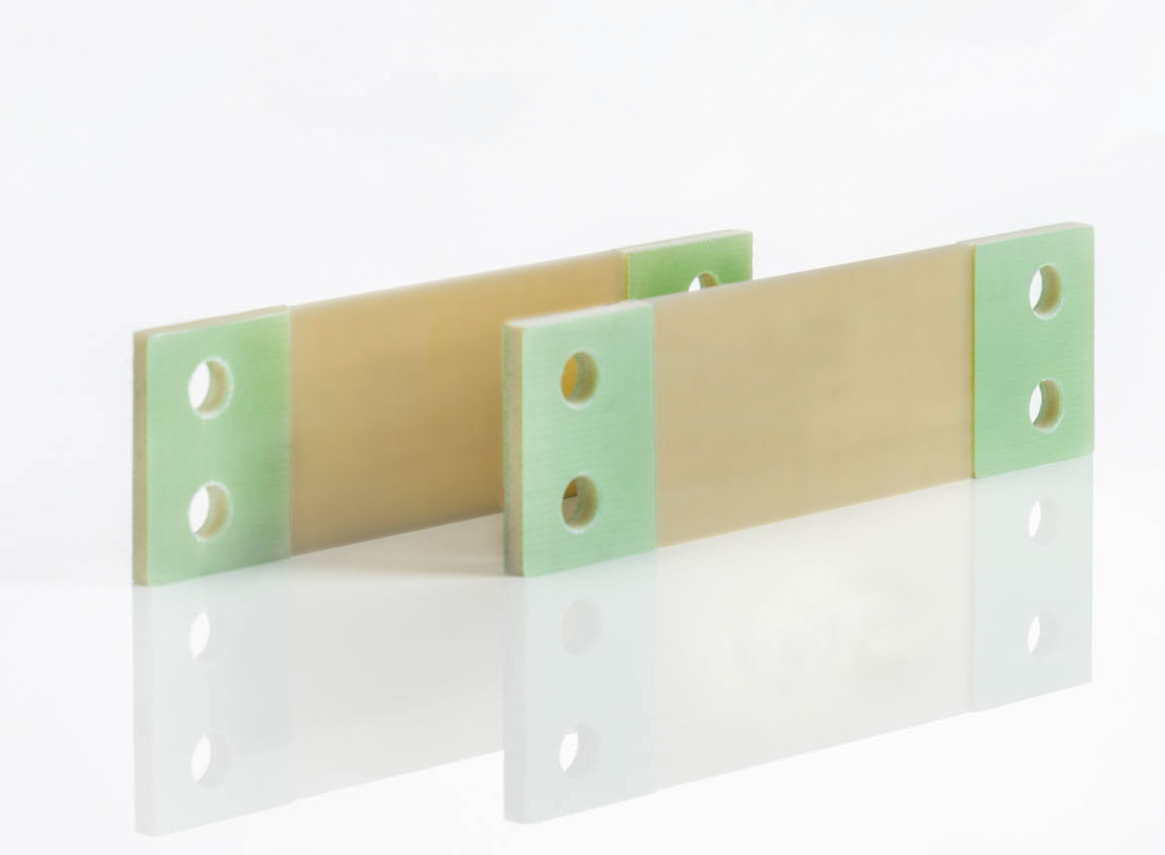

ScotchPLY is a high-performance glass-fiber reinforced epoxy composite renowned for its exceptional strength, stability, and durability. Such impressive performance, along with outstanding electrical insulation and fatigue resistance, makes ScotchPLY a top choice for industries ranging from manufacturing to aerospace.

Mechanical Strength and Fatigue Life

ScotchPLY is renowned for its exceptional strength-to-weight ratio, with a tensile strength of 960 MPa, flexural strength of 1150 MPa, and an elastic modulus of approximately 38 GPa. Despite being significantly lighter than steel (density ~1.8 g/cc), it offers high stiffness and outstanding load performance. Wohler curve testing also shows no fatigue failure beyond 10⁸ load cycles, making ScotchPLY an ideal replacement for metal springs in applications such as leaf springs.

Dimensional Stability

Beyond strength, ScotchPLY offers excellent dimensional stability and thermal resistance. Its unidirectional fiberglass and epoxy matrix yield a low thermal expansion (~8.6×10⁻⁶/°C). Standard grades operate from -60°C to +120°C, while high-temperature variants endure up to 180°C. This thermal resilience, along with strong creep resistance, ensures consistent performance from cryogenic to high-heat industrial environments.

Material Comparison

| Property | Standard ScotchPLY | Spring Steel: AISI 1060 | Steel: Mild (ASTM A36) |

| Tensile Strength | 960 MPa | 620–740 MPa | 400–550 MPa |

| Flexural Strength | 1150 MPa | 600 MPa | 400 MPa |

| Elastic Modulus | 38 GPa | 200 GPa | 200 GPa |

| Density | 1.8 g/cm³ | 7.85 g/cm³ | 7.85 g/cm³ |

| Fatigue Resistance | Excellent: no distinct fatigue limit. | High: endurance limit 300 MPa | Moderate: endurance limit 200 MPa. |

| Thermal Range | –50°C to 120°C | Up to ~400°C | Up to ~500°C for structural use. |

| Corrosion Resistance | Excellent: will not rust. | Poor: rusts readily if not painted or plated. | Poor: rusts if unprotected. |

| Electrical Insulation | Yes: electrically insulating. | No: highly electrically conductive. | No: conductive and magnetic. |

Recent Comments