Precision engineering is at the heart of what we do, and we’re proud to showcase the expertise and technology that drive our success. From reverse engineering complex components to high-volume CNC production, our team consistently delivers exceptional results. Choose from our extensive range of materials, including Engineering Plastics, Rubbers, & more!

Conveyor Line Audits – Upgrading to Dry Running Chains

Tynic offers conveyor audits to assess existing chains and identify opportunities for line efficiency improvements. By evaluating wear patterns, alignment, and material performance, we help optimise conveyor efficiency. Where suitable, we convert existing chains to Regina e-F.A.S.T. dry-running chains, reducing lubrication needs, minimising maintenance, reducing WHS incidents, and extending service life. Our audits ensure smoother operation, improved reliability, and long-term cost savings for your production line.

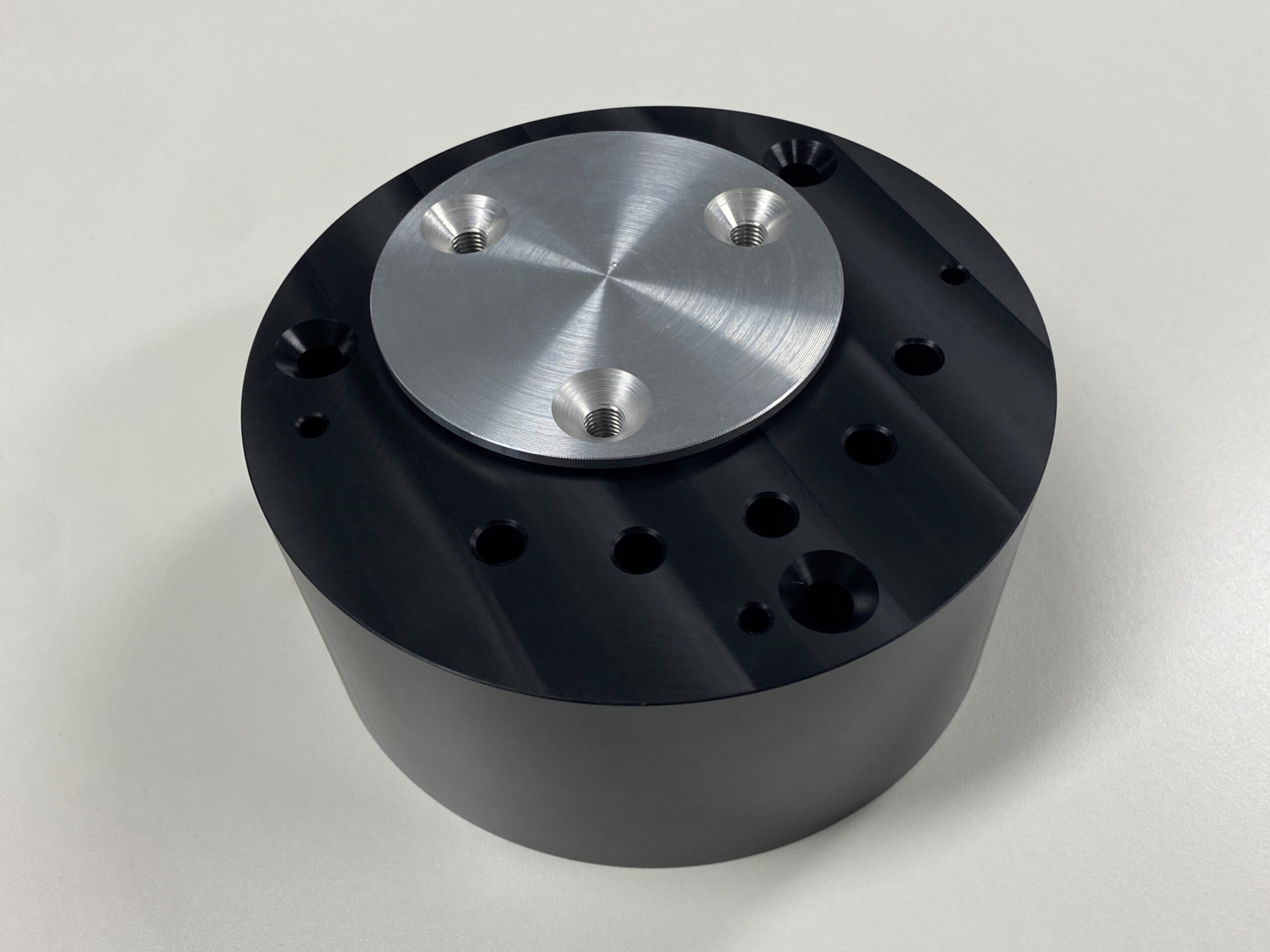

Acetal Spring Bearing Assembly

One of our valued customers engaged us to reverse engineer and manufacture a precision assembly set of spring bushes for a transport application. Leveraging advanced 3D scanning technology, our engineering team captured the exact geometry of the components, developed high-accuracy CAD models, and programmed CNC machining processes for optimal precision. The result? A high-quality machined finish that exceeded customer expectations.

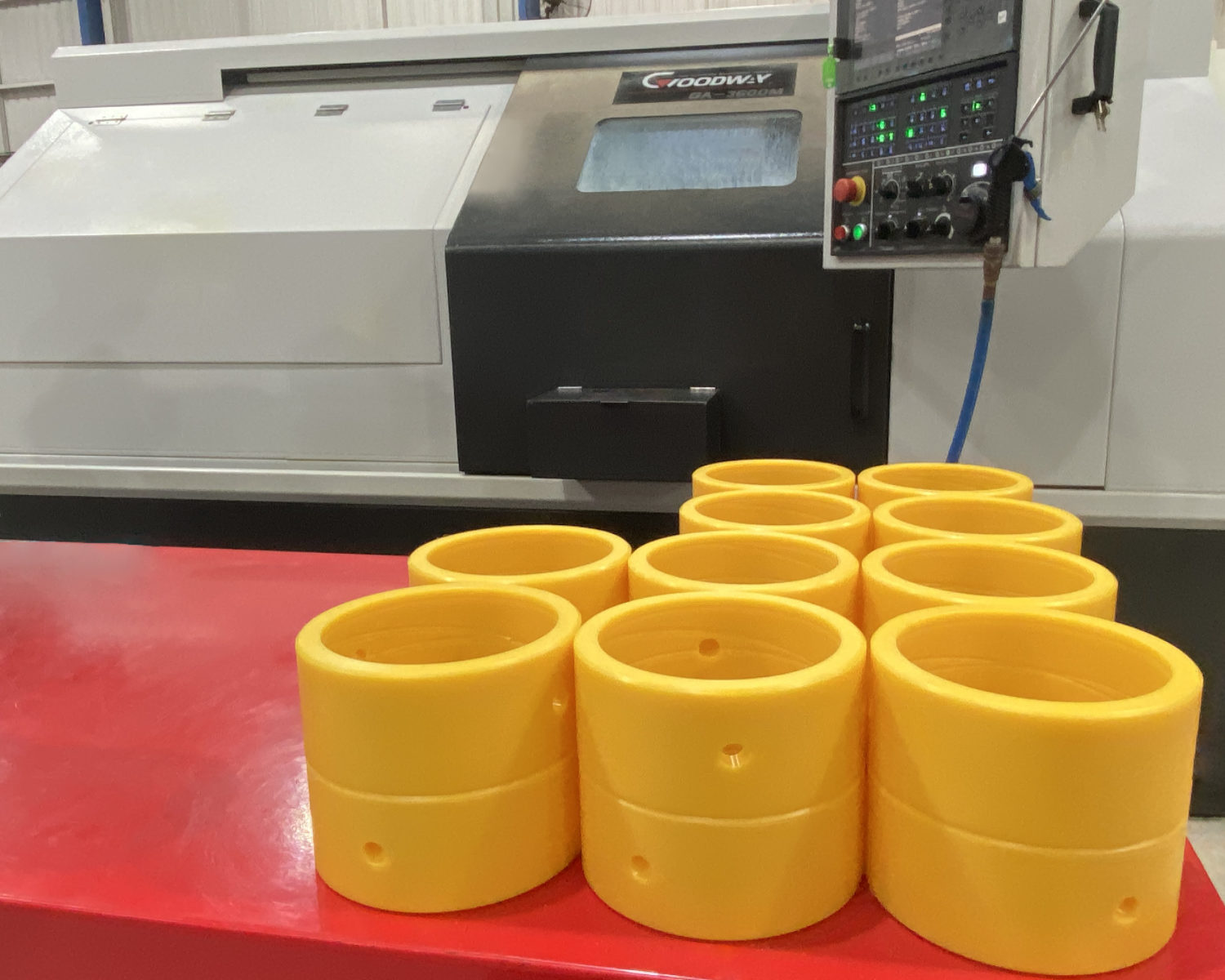

Oil Filled Nylon Bushes

With three CNC lathes equipped with live tooling, our engineering production team efficiently manufactures high-volume precision components. This capability proved invaluable when tasked with mass-producing Oil-Filled Nylon bushes for one of our largest customers. Leveraging advanced machining techniques, one of our skilled apprentices achieved exceptional surface finishes and successfully delivered the order ahead of schedule.

Recent Comments