Precision engineering is at the heart of what we do, and we’re proud to showcase the expertise and technology that drive our success. From reverse engineering complex components to high-volume CNC production, our team consistently delivers exceptional results to industry.

OEM Replacement Feed Screws

Tynic manufactures OEM replacement feed screws tailored to your production line. Every detail, from pitch and diameter to rotation direction, is engineered to match your unique requirements. To simplify maintenance, each screw can be inscribed with part numbers and critical specifications, reducing the chance of mix-ups during replacement. By combining precision machining with durable materials, our team ensures your feed screws deliver consistent, long-term performance.

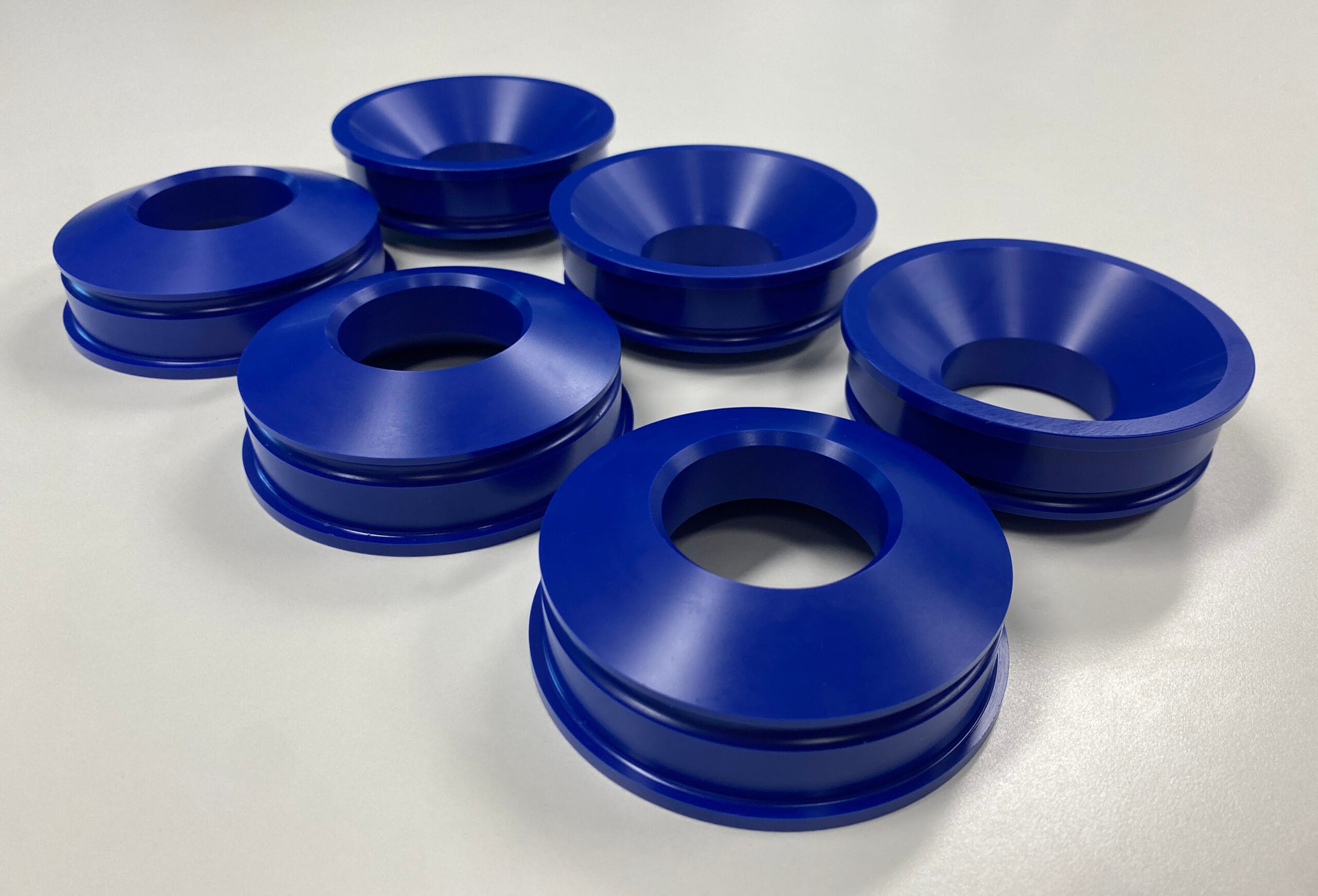

Metal Detectable Acetal Nozzles

To meet a client’s strict food safety standards, we recently manufactured a set of metal detectable acetal nozzles. The use of this specialist material ensures that even the smallest fragments can be identified by standard detection systems, protecting product integrity.

Custom Manufactured Foam HDPE Bins

A food and beverage client required a custom solution for storing sensitive production equipment. Our team designed and manufactured the storage bins from foam HDPE. This material provides good chemical resistance while remaining lightweight, making it easy to handle. The result was a tailored storage solution that not only met hygiene requirements but also improved efficiency for the client’s staff.

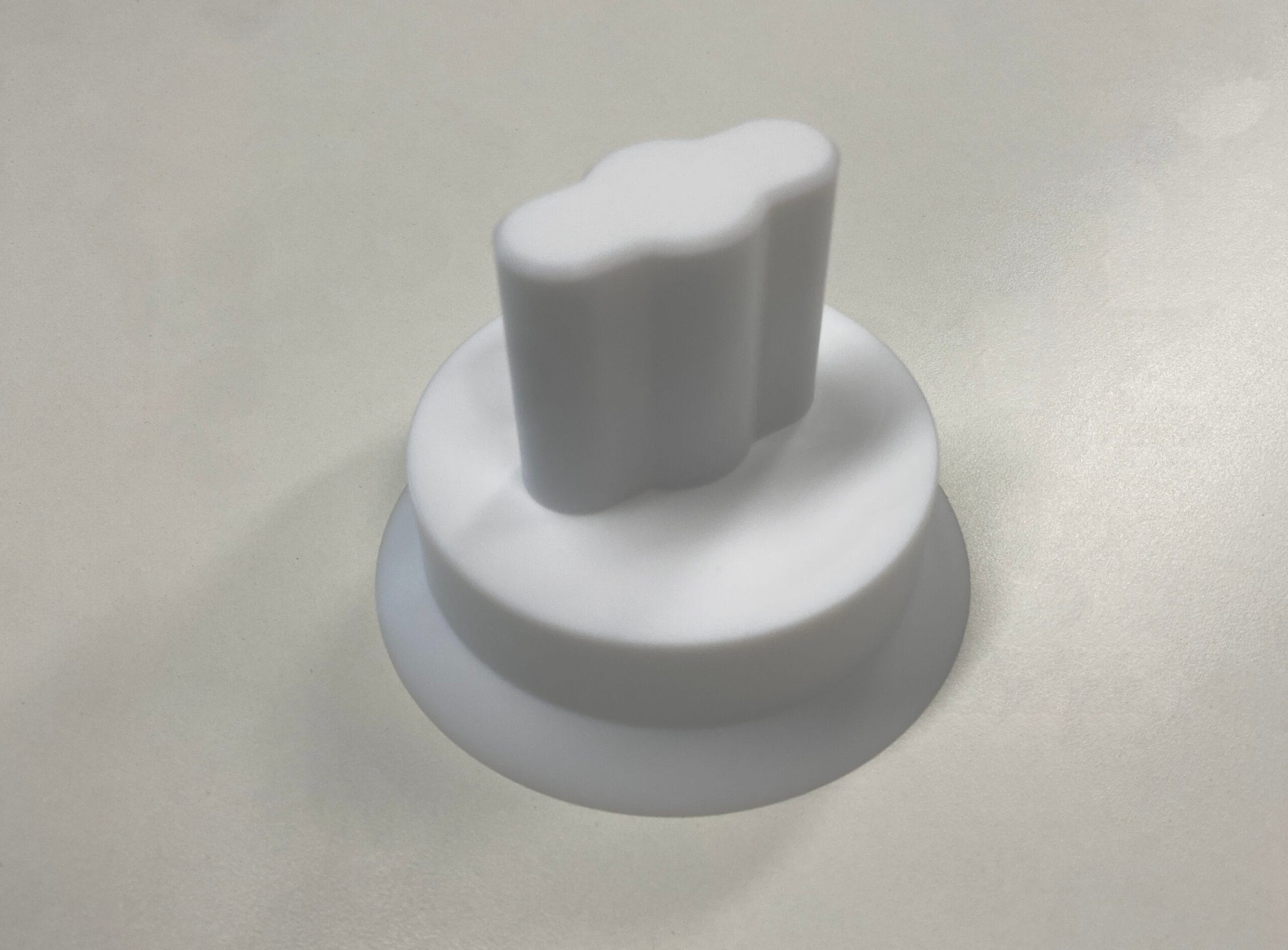

PTFE Centring Components

Tynic’s machining division recently completed the manufacture of 250mm diameter natural bushes for an industrial application. These large-diameter components were produced to precise specifications to ensure durability and reliable performance in demanding operating conditions.

Recent Comments