Identifying the Engineering Plastic material of an OEM component or an old spare part can be challenging. Simple tests, like density, burn, and tactile assessments, offer valuable clues to determine the polymer type. This guide outlines practical methods to support machining, replacement, or reverse engineering decisions.

Tactile Assessments

Float Tests

Burning Observations

1. Tactile & Visual Assessments

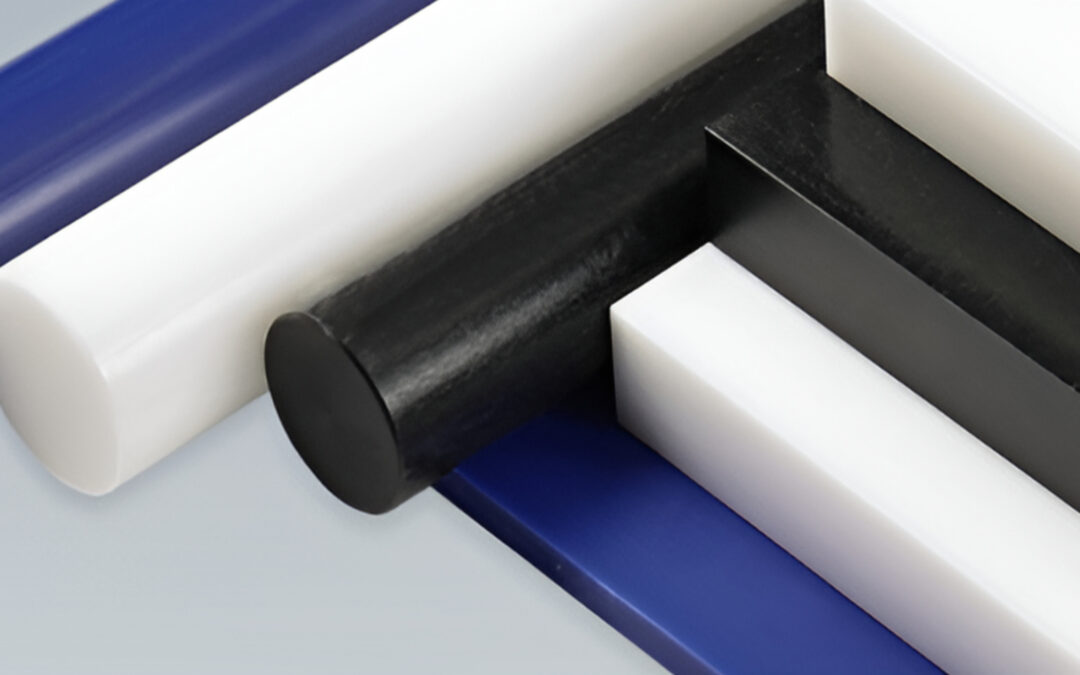

Identifying engineering plastics often begins with observing the material’s appearance and feel. Characteristics such as colour, texture, transparency, and flexibility can provide useful clues. Some plastics may appear glossy or waxy, while others feel rigid or rubbery. These observations help narrow down the possibilities before conducting physical tests.

| Material | Appearance | Texture / Feel |

|---|---|---|

| HDPE | Matte, waxy white or colored | Waxy, flexible, light |

| UHMWPE | Dull white, opaque | Very waxy, slippery, low friction |

| Nylon (PA6C) | Slightly glossy | Smooth, rigid, may absorb moisture |

| Acetal (POM) | Glossy, often natural or black | Very smooth, heavy, slick |

| PET | Dull, clear or grey | Hard, smooth, brittle |

| Polycarbonate (PC) | Transparent or tinted, glossy | Smooth, tough, slight flex |

| PTFE | Chalky white | Very slippery, soft, waxy |

| PEEK | Brown/grey, semi-crystalline | Hard, rigid, dense, slight texture |

2. The Float Test

The float test uses water to assess a material’s density. Plastics with a density lower than water will float, while denser materials will sink. This test is quick and non-destructive, making it a useful way to distinguish between common low-density and high-density engineering plastics.

| Material | Density (g/cm³) | Float in Water? |

|---|---|---|

| HDPE | 0.94–0.97 | Yes |

| UHMWPE | 0.93–0.94 | Yes |

| Nylon (PA6C) | 1.13–1.15 | No |

| Acetal (POM) | 1.39–1.42 | No |

| PET | 1.34–1.40 | No |

| Polycarbonate (PC) | 1.20–1.22 | No |

| PTFE | 2.13–2.20 | No |

| PEEK | 1.30–1.32 | No |

3. Burn Observations

The burn test involves carefully applying a flame to observe how the plastic behaves, such as how easily it ignites, the colour of the flame, and the type of smoke or odour produced. These combustion traits vary between plastics and can help identify the material.

Caution: Always conduct burn tests in a controlled environment with proper ventilation and PPE.

| Material | Flame Behavior | Other Observations |

|---|---|---|

| HDPE | Blue flame with yellow tip, drips, not self-extinguishing | Minimal smoke, paraffin/waxy odor |

| UHMWPE | Blue-yellow flame, drips, harder to ignite | Minimal smoke, candle-like odor |

| Nylon (PA6C) | Blue-yellow flame, drips, continues burning | Minimal smoke, smells like burning hair/celery |

| Acetal (POM) | Blue, low-intensity flame, drips, not self-extinguishing | No visible smoke, strong formaldehyde odor |

| PET | Yellow flame with blue base, drips, vigorous burn | Dense black smoke, sweet/chemical smell |

| Polycarbonate (PC) | Orange/yellow flame, drips, self-extinguishing | Heavy black smoke, phenolic odor |

| PTFE | Does not burn, shrinks or deforms | No visible smoke; faint chemical odor only at extreme heat |

| PEEK | Hard to ignite, chars, self-extinguishing | Very low smoke, faint aromatic odor, black char residue |

Recent Comments