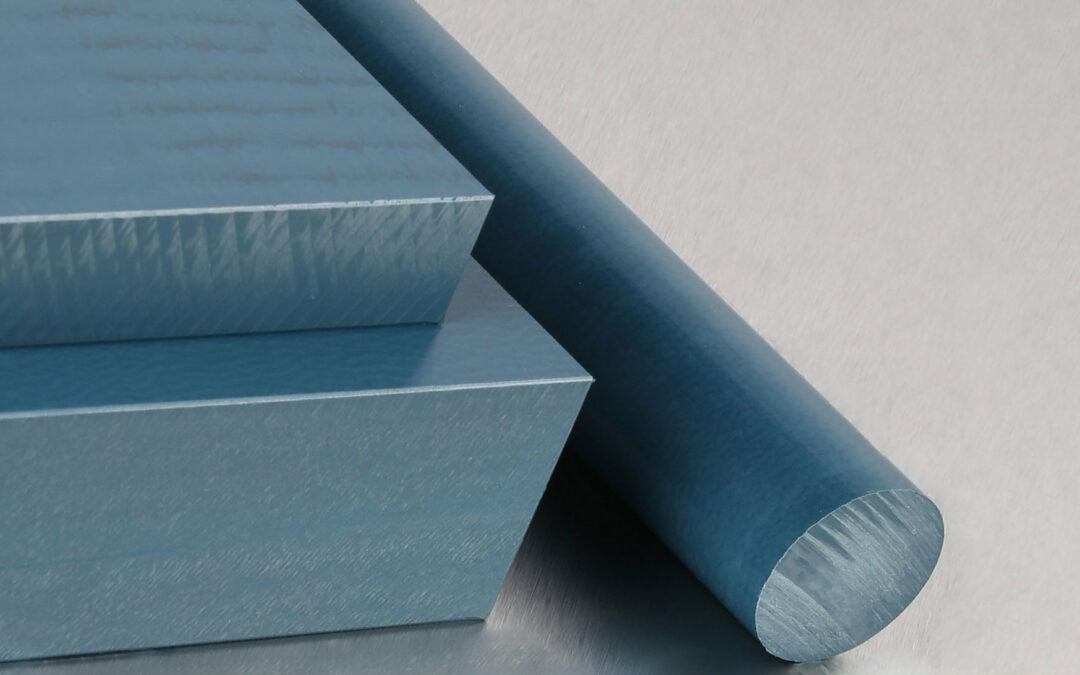

At Tynic Automation, we recognise that effective detection of foreign materials is essential to maintaining product integrity and safety in food processing and packaging environments. Blue engineering plastics are widely adopted due to their superior visibility and detectability within automated inspection systems.

Why Choose Metal Detectable Materials?

In the event of component wear or breakage, fragments can be quickly identified and removed, reducing the risk of contamination and ensuring ongoing compliance with food safety standards. Tynic Automation supplies a wide range of metal-detectable engineering plastics, designed for use in demanding food production environments. Our materials combine excellent mechanical performance, chemical resistance, and detectability, making them suitable for use in conveyor systems, machinery components, and processing equipment.

Available Metal Detectable Materials

Tynic Automation offers detectable grades across several commonly used engineering plastics, including:

- Acetal (POM)

- UHMWPE

- Teflon (PTFE)

- Nylon (PA6C)

Applications

Metal detectable plastics are used throughout the food production line, but they’re particularly effective in:

- Conveyor componentry

- Wear strips and guides

- Scrapers, paddles, and transfer parts

Recent Comments