At Tynic Automation, we specialise in reverse engineering and machining of OEM components, helping businesses break free from costly proprietary parts. See below for a step-by-step look at our reverse engineering process and how we deliver precision-engineered solutions.

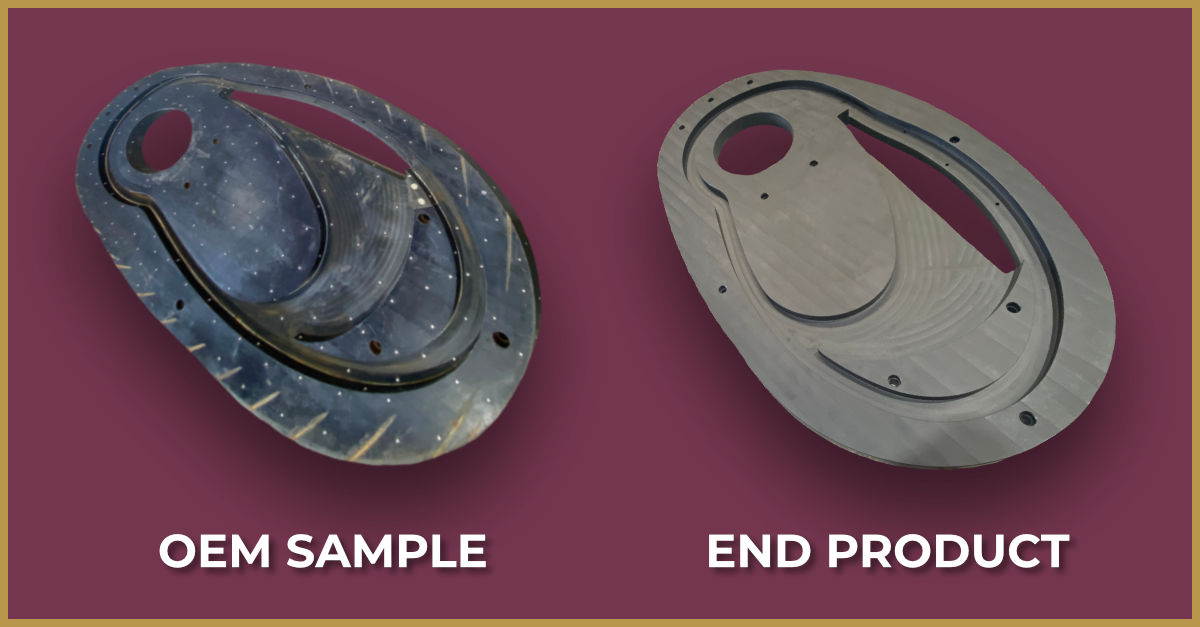

Nylon CAM Follower Plate

Our engineering team was recently tasked with reverse engineering a complex Nylon Cam Follower Plate sample that was warped, worn, and structurally compromised. Using our 3D scanner, we were able to produce a high-precision, cost-effective replacement. The final component was a perfect fit and was immediately installed into the production line, ensuring seamless integration and reliable performance

Our Process

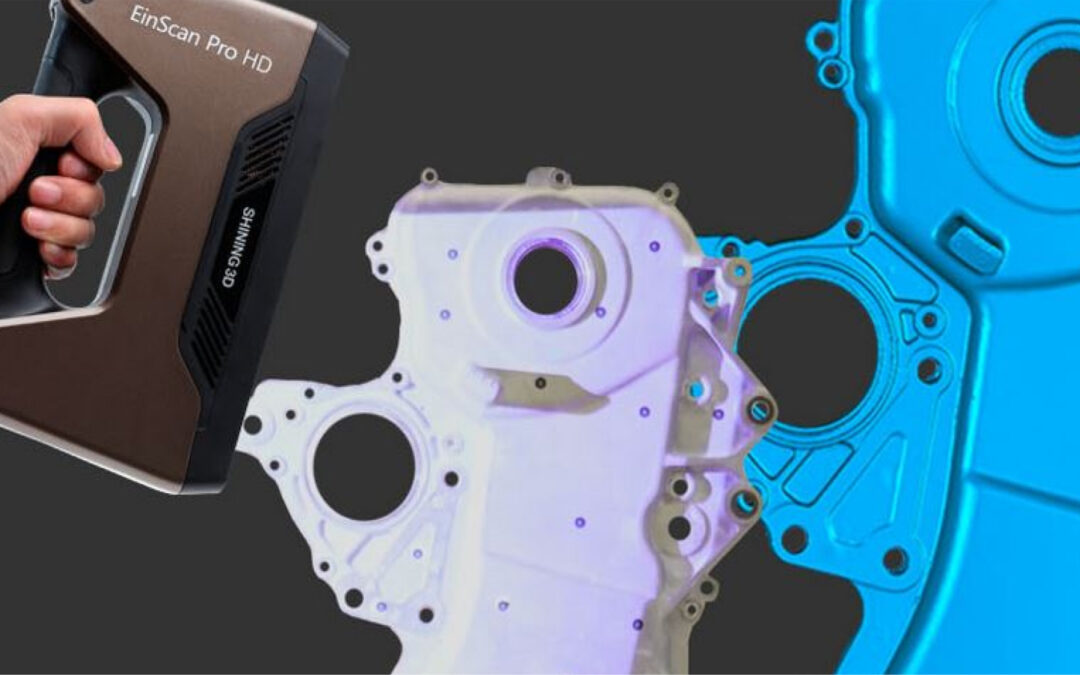

1. 3D Scanning

3D scanning is a critical step in the reverse engineering process, allowing us to capture highly accurate digital models. With a volumetric accuracy of ±0.1mm, our technology captures even the finest details. This level of accuracy minimizes errors, reduces lead times, and enables us to manufacture high-quality replacements.

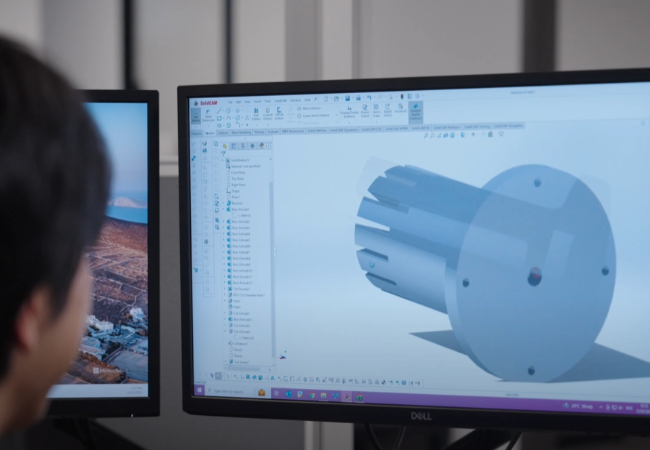

2. Modeling

Utilizing SolidWorks, our team transforms these scans into detailed 3D models, ensuring accuracy and compatibility with existing systems. This integration of 3D scanning and modeling allows us to efficiently reproduce complex parts, offering cost-effective alternatives to OEM components without compromising on quality.

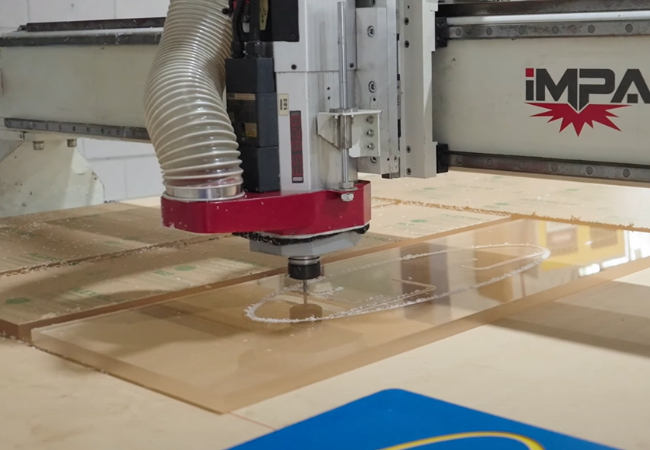

3. Programming

Using CAM software, we generate toolpaths and precise machining instructions, ensuring every cut, hole, and chamfer matches the original specifications. Our experienced team optimises cutting speeds, tool selection, and machining strategies to maximize accuracy while minimizing material waste and production time.

4. Machining

With a fleet of CNC machines, Tynic Automation produces high-precision components at scale. Whether milling, turning, or multi-axis machining, our equipment handles complex geometries, maintaining tight tolerances for seamless integration. By investing in technology, we provide a cost-effective alternative to overpriced OEM components.

5. Quality Control

Quality control is the final step in our process, ensuring every component meets strict dimensional and performance standards. Our engineers require full dimensional checks from another team member, providing an extra layer of verification for accuracy and consistency.

Recent Comments